| The Slitting Method for Residual Stress Measurement: : Aluminum plate |

Biaxial residual stress measured in aluminum plate before and after stress relief

M. B. Prime and M. R. Hill, "Residual Stress, Stress Relief, and Inhomogeneity in Aluminum Plate," Scripta Materialia, 46, pp. 77-82, 2002. preprint (pdf) . (LA-UR-01-4723)

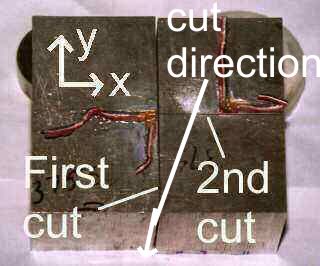

Two Specimens:3-inch (75 mm) thick rolled 7050 Aluminum, 6 inch by 6 inch (150 mm by 150 mm) blocks

Two cuts each specimen:

|

Strain data

Strain data |

The Results:

|

|

|

NOTE: The raw data from this test and any other data I have can be made available for research purposes. Just email me.