Chemical Processes and Applied Technologies

Contact Us

- GroupLeader

- Peter Stark

- Deputy Group Leader

- Dan Kelly

- Group Office

- (505) 667-5740

Material Synthesis and Extraction, Chemical Separations, and Polymer Development

The Chemical Processes and Applied Technologies Team in the Chemical Diagnostics and Engineering group of the Chemistry Division provides support to a variety of projects at Los Alamos National Laboratory with benefits to the local community and support for global environmental efforts.

Capabilities

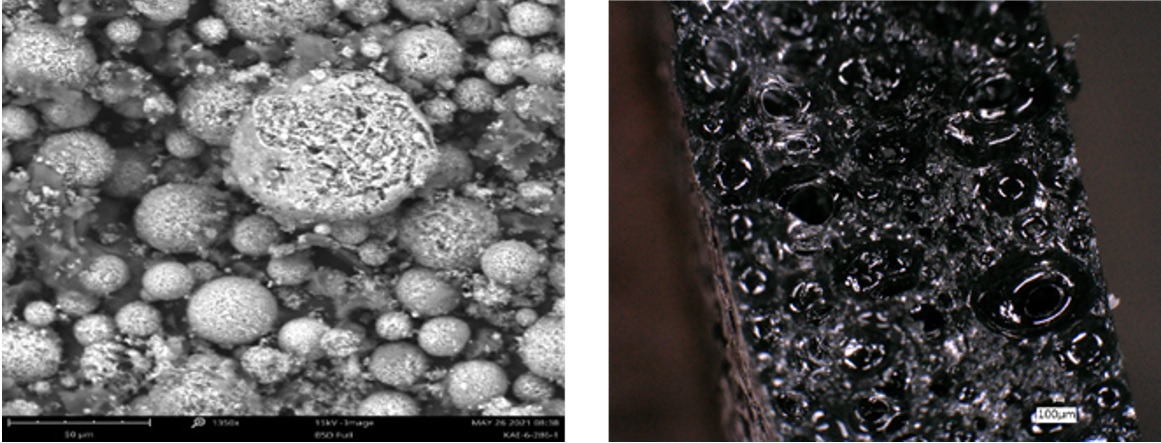

- Particle / suspension properties

- Analytical centrifugation

- Particle settling behavior and stability

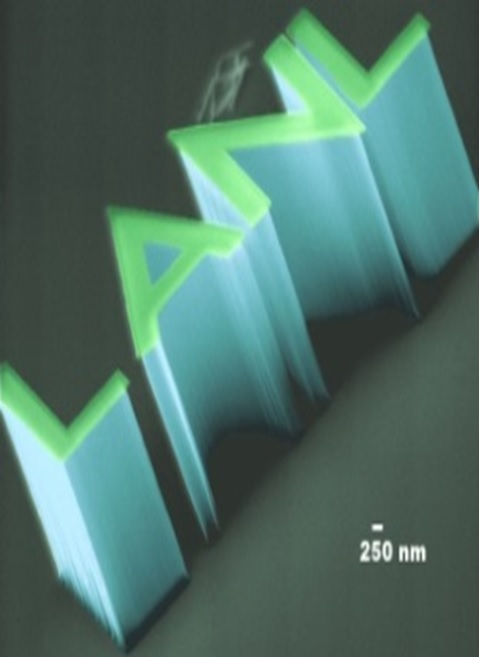

- Broad ultrasonic filtration capabilities and assessments

- Membrane screening and performance characteristics

- Centrifugation dynamics

Projects

- Microalgae dewatering

- Biomaterials separations for biofuels production

- Mineral ultrasonic filtration

- Heat source solids recovery

Capabilities

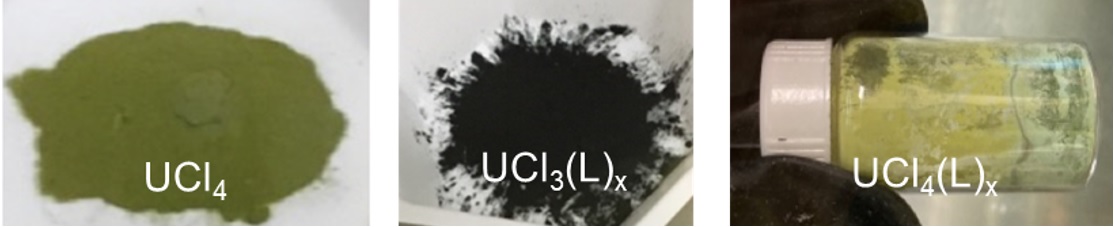

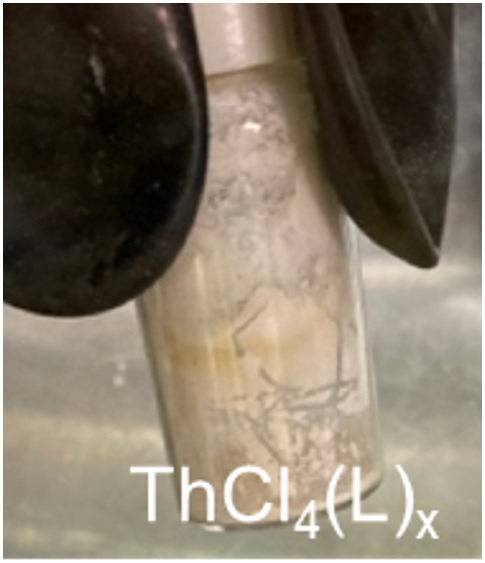

- Expanded synthetic actinide capabilities

- Materials synthesis

- 433 sq ft non-rad lab

- Inert single and double gloveboxes

Projects

- Air-free actinide synthesis and characterization

- Advanced Gen IV nuclear reactor fuels

- Materials synthesis

- Developing Pu new capability based on new synthetic actinide gloveboxes

- Surface functionalization actinide organometallic complexes

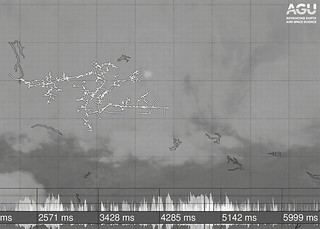

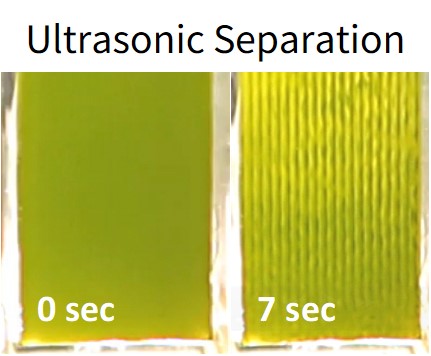

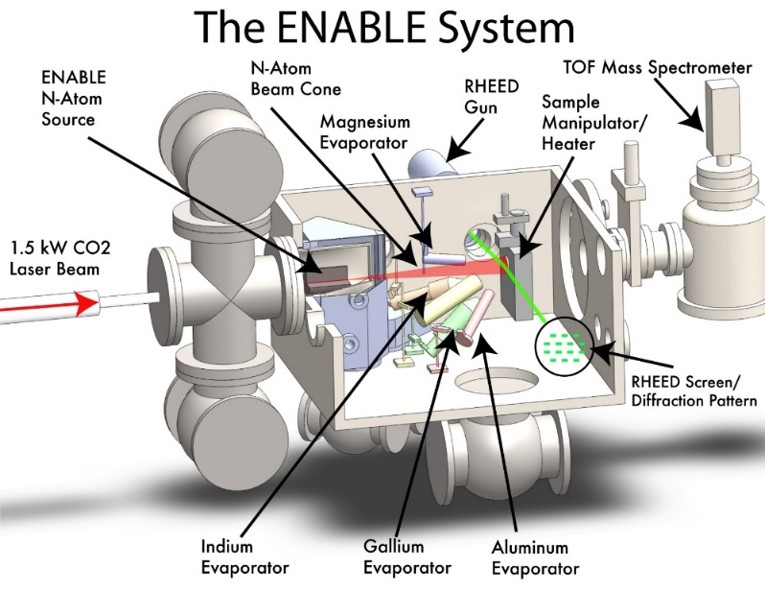

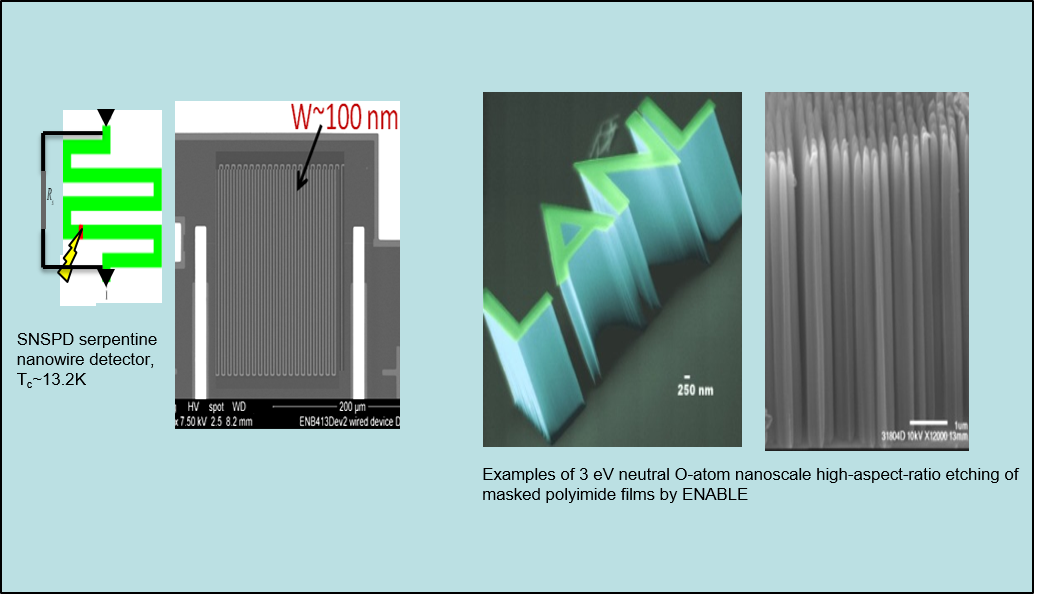

ENABLE (Energetic Neutral Atom Beam Lithography & Epitaxy) is a unique MBE-type film growth technology that uses a high-flux beam of energetic neutral nitrogen or oxygen atoms with kinetic energies of 1 to 5 eV to overcoming reaction barriers intrinsic to thin film growth. The system allows high growth rates of a wide variety of epitaxial, highly-crystalline, wide-bandgap nitride and oxide semiconducting films with excellent physical, optical, and electronic properties.

Capabilities

- Growth of wide- and ultra-wide bandgap nitride and oxide semiconductors

- Development of tunable bandgap Indium-Gallium-Aluminum Nitride films

- Growth of Boron-rich nitride semiconductors

- Growth of Niobium Nitride ultrathin films

- High-aspect-ratio nanoscale polymer etching

Projects

- High-power/high-frequency power electronics

- Energy applications involving solid state lighting, photovoltaics, and photoelectrochemical water splitting (hydrogen production)

- Solid-state neutron detectors

- Superconducting nanowire single photon detection based on ultrathin films

- Novel devices based on high-aspect-ratio structures

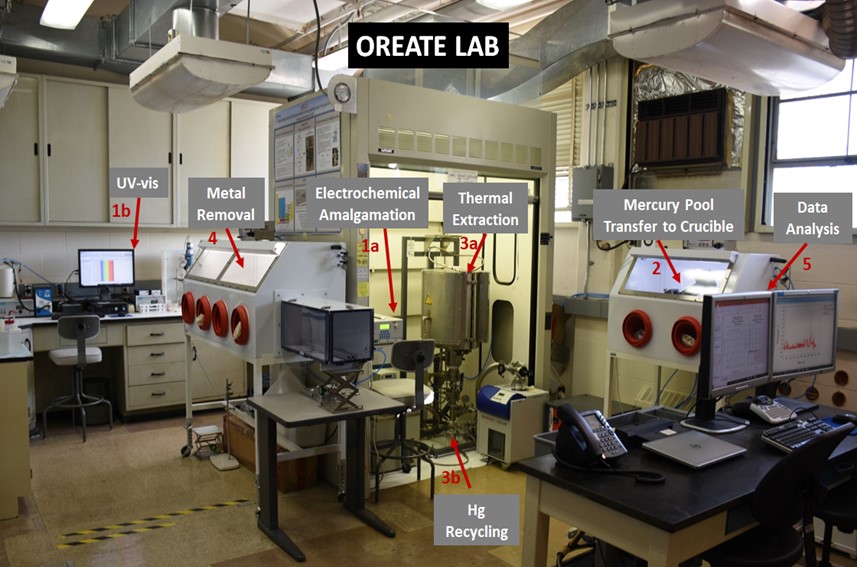

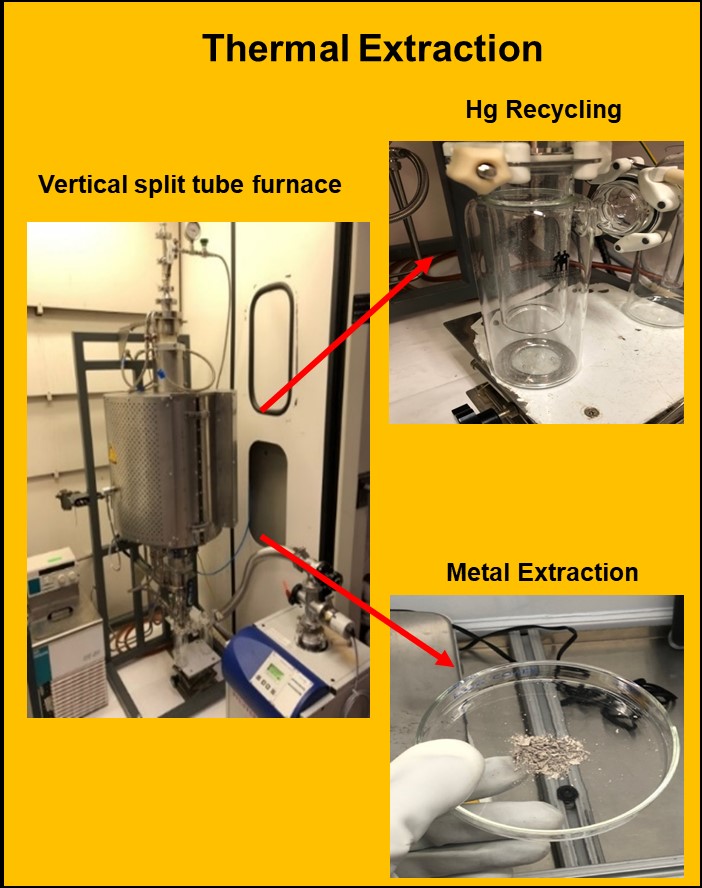

OREATE being developed at LANL is considered the answer to producing high-end actinide metal products with near quantity yield. This process can be used to produce an efficient and clean metal feed and as a post-process for recycling of purified material that resulted in chemical conversion (ie. oxidation).

Capabilities

- Electroanalytical chemistry

- Electrochemical processes involving transition metals, lanthanides and actinides chemistry

- Thermal extraction of metals by mercury distillation

Projects

- Electrochemical reduction and dissolution of metal oxides

- Purification of transition metals, lanthanides and actinides

- Preparation of pure metal feeds for isotope separations

- Recovery and recycling of metals of interest from waste streams

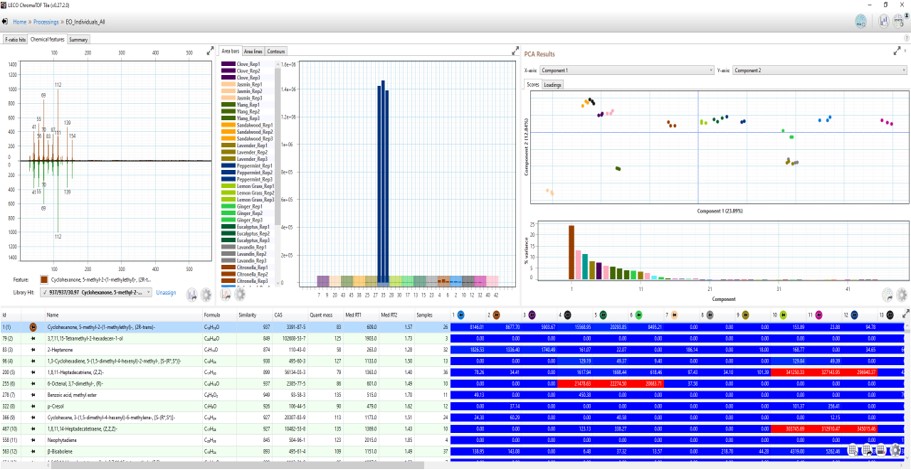

Capabilities

- Compressive 2-Dimensional GC Separations using Quad-Jet Thermo Modulator

- High-Resolution Exact Mass Time of Flight Mass Spectrometer

- Liquid Injection, Headspace, and SPME Analysis

Projects

- Metabolomics

- Chemical Forensics

- Petroleum and Biofuels

- Environmental Monitoring

- Essential Oils and Fragrances

Capabilities

- Machine Learning accelerated biopolymer discovery, design, and development

- Synthesis and analysis of new biopolymers

- Development of transparent shielding polymers

- Removal of silica scale

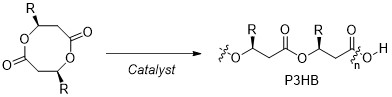

Synthesis of Bioplastics

Transparent Shielding Polymers

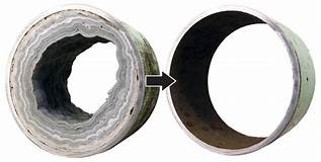

Silica Scale Removal from Utilities

Projects

- Microalgae-derived biopolymers developed to produce novel bioplastics to replace petroleum-based plastics and reinvent the lifecycle of plastics

- Development of low-cost, lightweight, and more effective transparent shielding polymers

- Silica scale reduction at LANL utility sites

- Development of simple, inexpensive methods of reducing silica concentration in local water supplies