Trace Analytical and Material Characterization

Developing and supporting programs through chemical analysis, analytical methods and development, and material R&D

Contact Us

- Group Leader

- Peter Stark

- Deputy Group Leader

- Dan Kelly

- Group Office

- (505) 667-5740

Chemical Analysis, Material R&D, and Development of Analytical Instrumentation

The Trace Analytical and Material Characterization Team in Chemistry Division's Chemical Diagnostics and Engineering group provides analytical chemistry and R&D science and engineering for a wide variety of LANL programs including Science and Engineering Campaigns, WR Pit and Detonator Production, and the Weapons Directorate. This work involves multidisciplinary staff and is materials science-based with analytical capabilities spanning the periodic table, from atomic to macroscopic length scales.

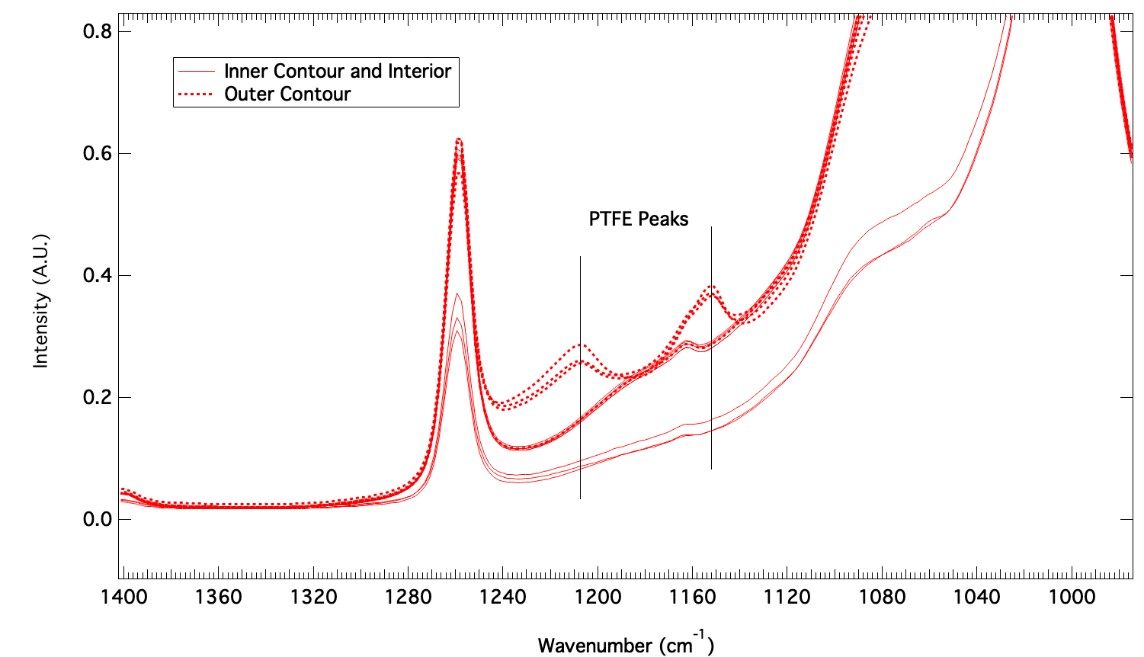

Our team develops and employs a variety of chemical analytical instrumentation (over 30 instruments), including laser induced breakdown spectroscopy (LIBS), gas chromatography mass spectrometry (GC-MS), x-ray photoelectron spectroscopy (XPS), x-ray fluorescence spectroscopy (XRF), scanning electron microscopy with energy dispersive spectroscopy (SEM-EDS), near- and mid-Fourier transform infrared spectroscopy (FTIR), ultraviolet-visible spectroscopy (UV-vis), to name a few.

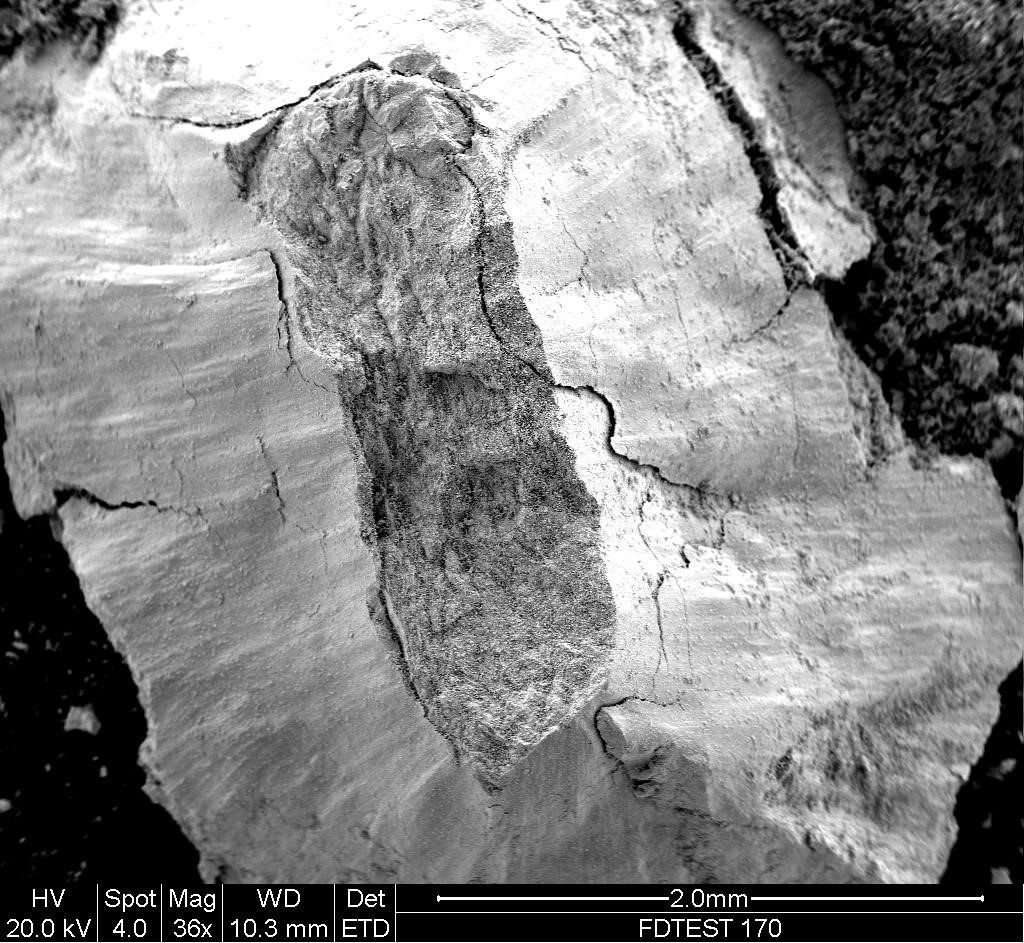

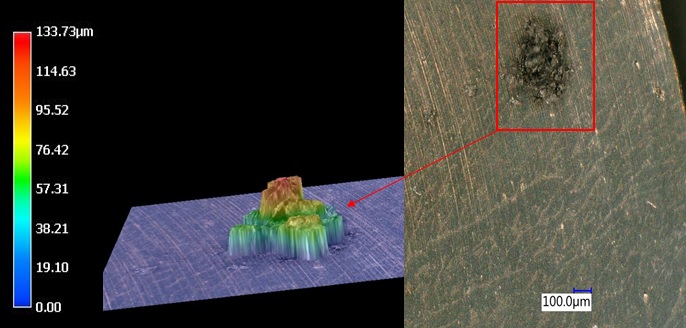

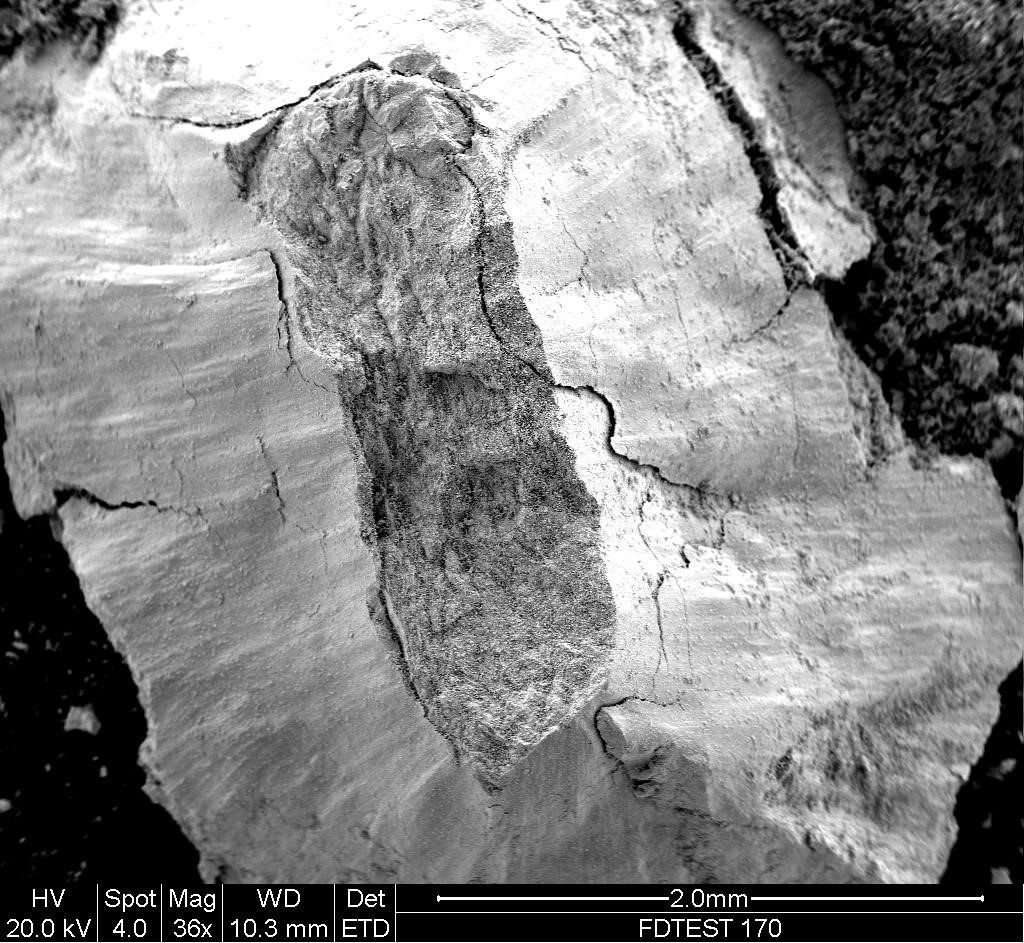

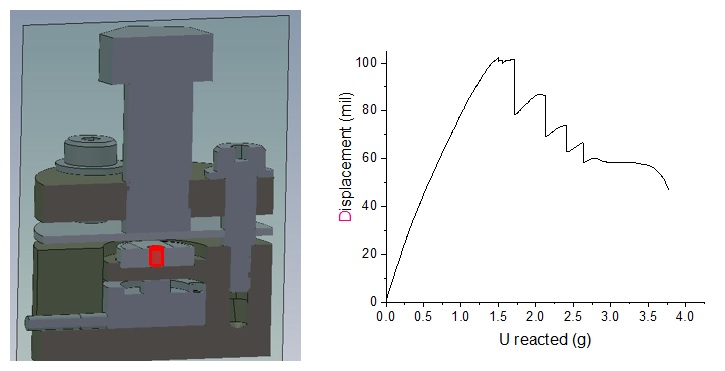

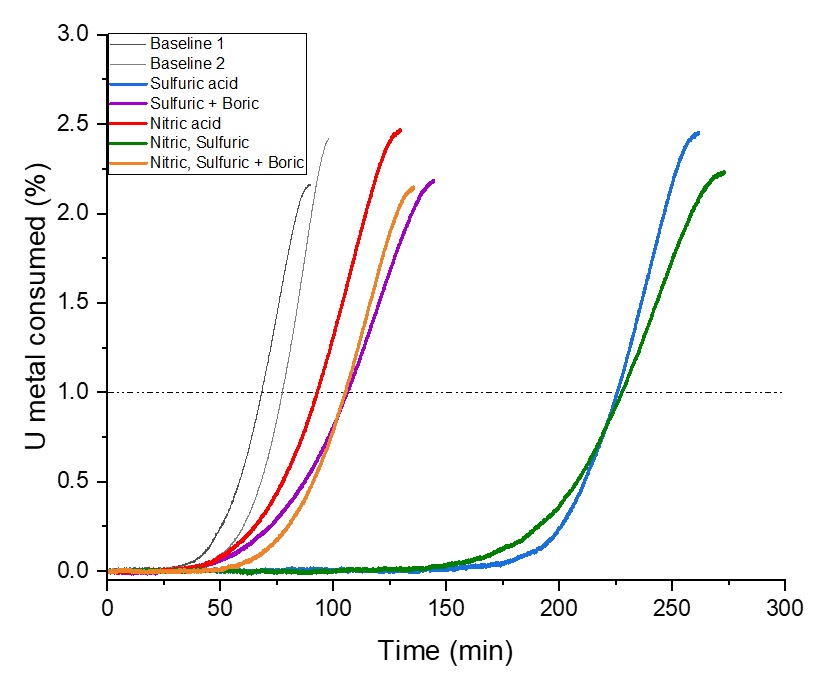

Our team extensively studies the mechanisms of uranium corrosion, and the compatibility of plutonium with Pit Manufacturing materials. Recent studies of uranium hydriding have elucidated the physical properties and mechanical behavior of the growing UH3 reaction product.

Uranium metal corrodes when in contact with O2 and H2 which induces stress within the metal and neighboring materials. The Chemical Diagnostics and Engineering group has the capability of investigating corrosion varying the environmental conditions of the metal and performing analytical measurements to understand the changes to the metal, neighboring materials, and environment under relevant storage conditions.

Our team has expertise in polymeric materials used for cushioning in high-performance engineered applications. We have provided engineers and designers SME support and analysis from development to WR production. This work helps ensure process control at the production agency.

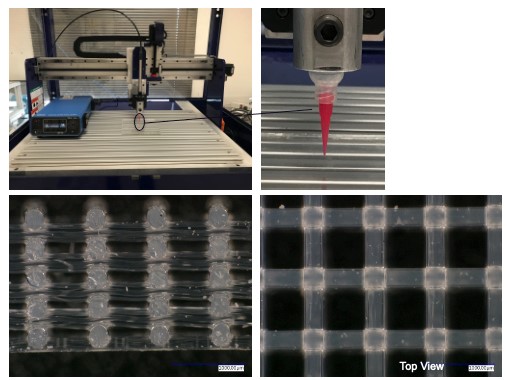

In addition to supporting current systems, we also develop technology for evaluation for future systems, often using Additive Manufacturing (AM). We have developed better aging silicone resins that are used in Direct Ink Write (DIW) technology to produce pads. In collaboration with MST-7, we are evaluating WR-production grade DIW equipment and also Selective Laser Sintering (SLS) as a method to produce complex thermoplastic components.

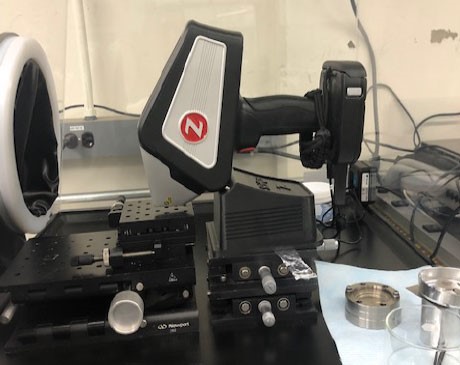

Our team has developed LIBS methods for radiological material and continues to collaborate within the Chemical Diagnostics and Engineering group and Chemistry Division.

LIBS is a laser-based technique that involves the use of a focused pulse laser beam to generate a microplasma. The emission from the plasma is wavelength resolved using a spectrograph/detector/computer system to determine the elemental composition of the samples of interest. We focus on building systems, optimizing COTS systems, and developing data analysis programs and user interfaces that are application specific.

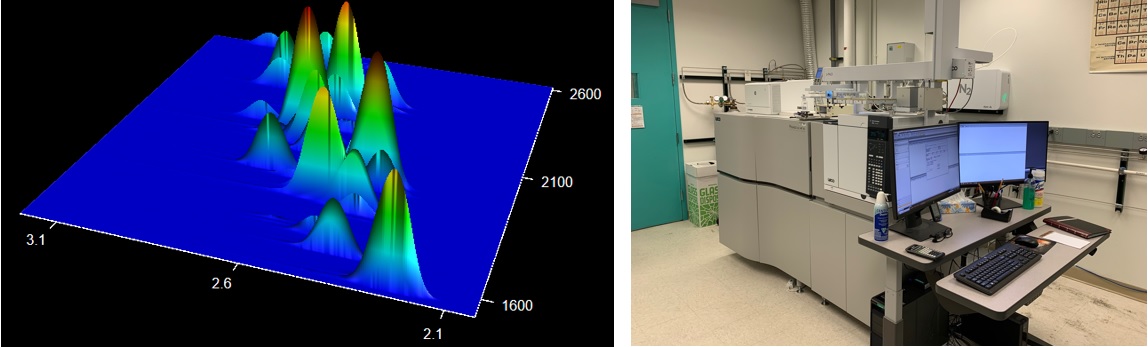

Our team has extensive expertise in gas chromatography (GC) methods used to support environmental protection efforts, weapons production, and exploratory weapons research. C-CDE applies a variety of detection methods to qualitatively identify and quantify compounds of interest in liquid and gas-phase sample matrices.

Gas chromatography-mass spectrometry (GC-MS) and two-dimensional GCMS (GCXGC-MS) methods have been developed to help mitigate the presence of legacy environmental contaminants present around the laboratory complex.

Additionally, GC coupled with thermal conductivity detectors (TCD) and nitrogen-phosphorus detectors (NPD) have been used to quantify analytes of interest in gas-phase samples collected from radiolysis and thermal aging studies. Moreover, our GC-MS systems are always on standby to support emergency analyses when identification of potentially hazardous compounds is needed.

Our laboratory can assist with the detection of nearly all volatile and semi-volatile compounds using a range of unique instrumentation.

The Chemical Certification and Compatibility Lab (C3Lab) is managed as part of the Trace Analytical and Materials Characterization Team.

C3Lab is an analytical lab operating to NAP-24A Weapons Quality policy, in support of LANL’s missions in Pit and Detonator manufacturing. This work certifies incoming materials, conducts multi-material compatibility testing, and develops new analytical capability in support of War Reserve Manufacturing at LANL.