Faster pit analysis

Laser-induced breakdown spectroscopy will help characterize pits quickly and accurately.

- Kenny Vigil, Communications specialist

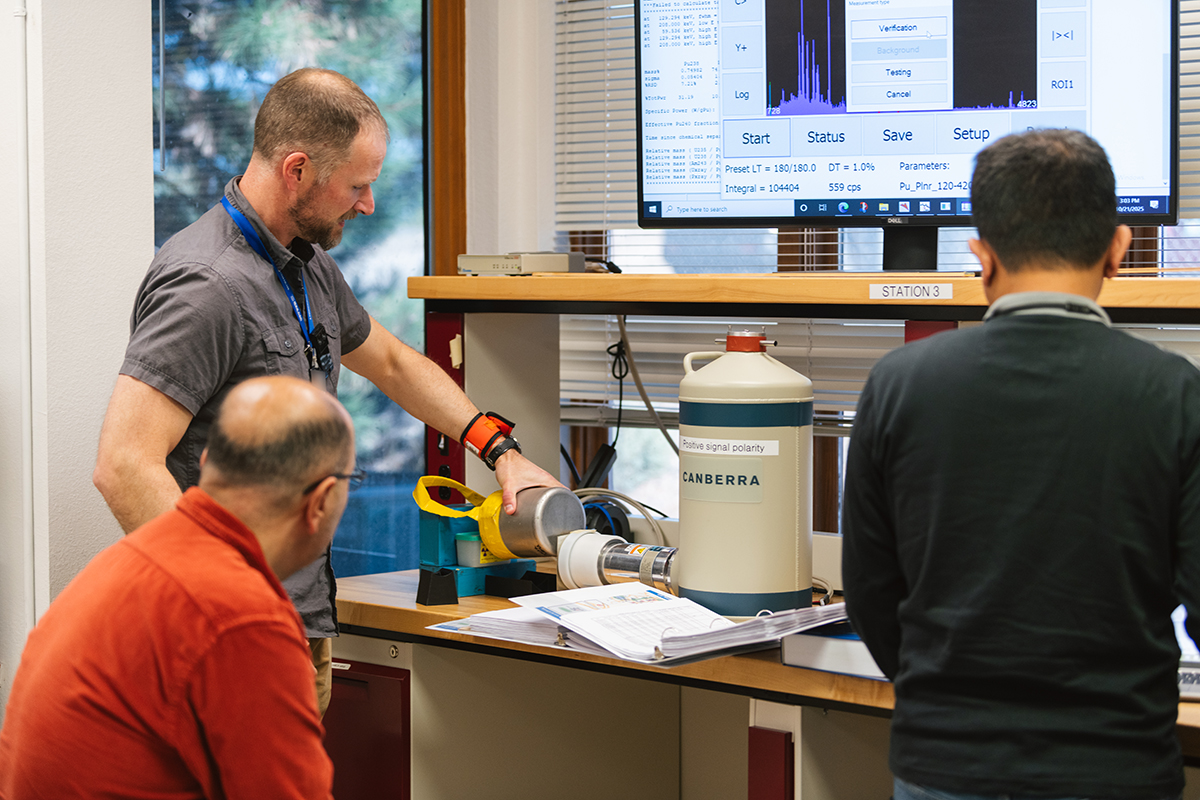

Currently, characterizing—studying the chemical composition of—plutonium pits involves sampling small amounts of plutonium at Los Alamos National Laboratory’s Plutonium Facility and then sending the samples to various other Lab facilities to be analyzed—a process that can take weeks.

But a recent collaboration between the Laboratory and the United States Air Force Institute of Technology (AFIT) resulted in an experiment and machine learning studies that determined laser-induced breakdown spectroscopy (LIBS) can be used to characterize pits in just seconds.

LIBS works by focusing a highly energetic laser pulse onto the surface of the plutonium. A micro-plasma of electronically excited atoms and ions is created on the sample surface. As these atoms decay back into their ground states, they emit characteristic wavelengths of light, or unique “fingerprints” that allow researchers to get an immediate characterization of the plutonium sample.

“LIBS can raise confidence in each step of the pit production process and change how we do pit manufacturing,” says John Auxier II, of the Lab’s Actinide Material and Processing Power division. LIBS is expected to help the Laboratory meet its goal to manufacture at least 30 pits per year starting in 2026.

Analysis of LIBS data takes only minutes. AFIT applied machine learning techniques to the data, which had never been done before. Machine learning uses models to understand patterns and make predictions, in this case, about the chemical analysis of plutonium.

“The machine learning allowed us to get quantification of impurities in plutonium,” explains Auxier, noting that in the future, additional machine learning technology developed at the Laboratory will also be used for data analysis.

“We can’t do pit production without the entire Lab behind us. It really requires the technical engine that is Los Alamos to support it,” Auxier says. “The science piece of this is really driving some exciting stuff.”