Why stretched graphene conducts heat on metal surfaces

Study aids efforts for advanced heat management in next-generation coatings

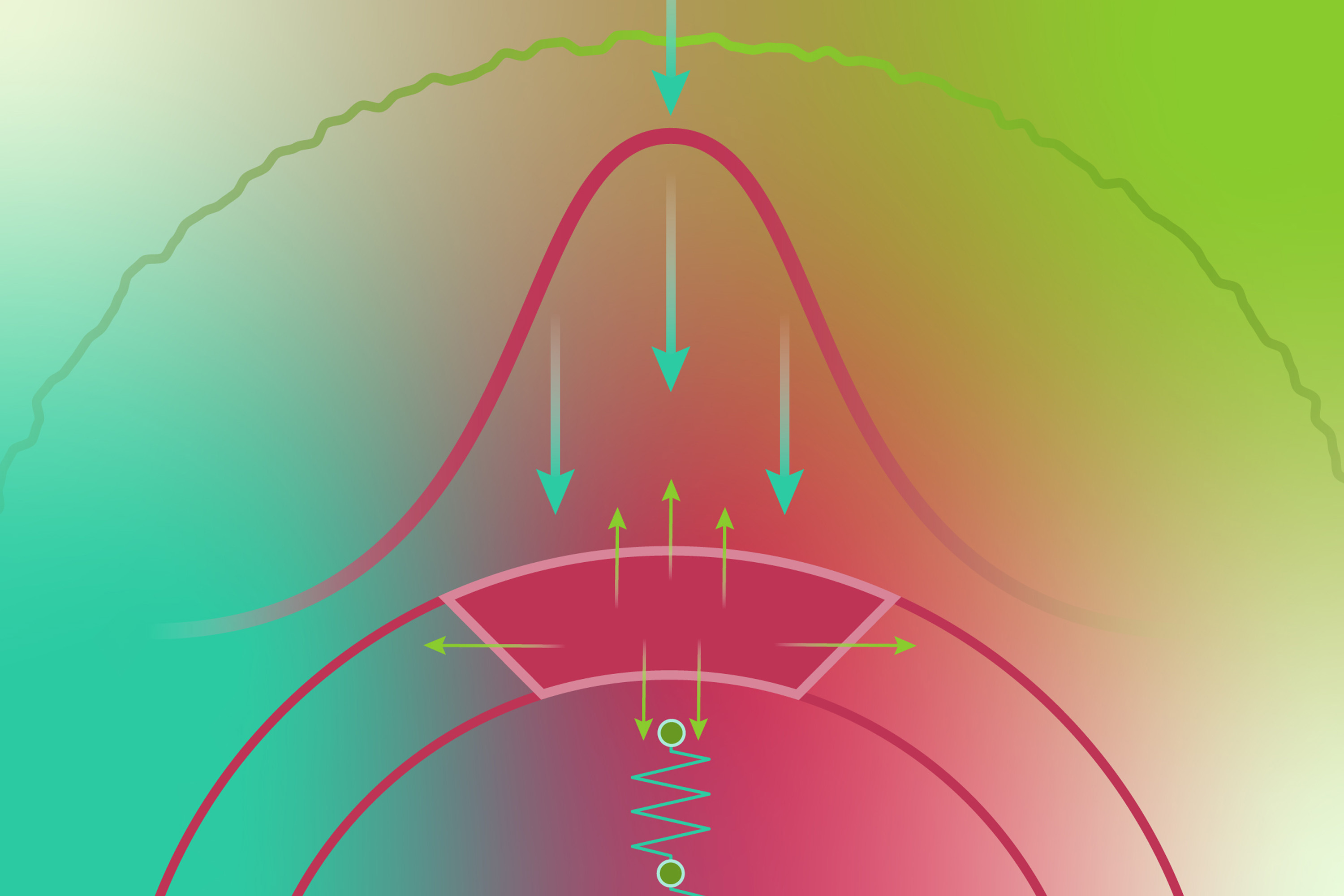

Graphene — even at only one atom thick — shows strong potential as a protective coating by resisting corrosion and efficiently diffusing heat to shield the underlying substrate. However, its thermal behavior under physical strain is not well studied.

In a first-of-its-kind experiment, Los Alamos materials researchers characterized how strain affects the thermal properties of a large-area graphene coating on a machined copper part. Their results showed that how well heat flows through the thin coating depends on both the material itself and how it connects to the metal subsurface.

The work was featured on the cover of a special issue of the Royal Society of Chemistry’s Nanoscale Advances.

Why this matters: Understanding changes in a material's thermal properties under mechanical deformation is challenging experimentally, yet components used in real-world applications routinely experience deformation in these conditions.

More on the science:

- This research builds on co-author Hisato Yamaguchi's R&D 100 Award-winning “Atomic Armor” technology, which has demonstrated potential for protecting specific metals against corrosion.

- This work leveraged a broad range of expertise from across the Lab, including the advanced manufacturing and coatings technology of Accelerator Operations and Technology division; the metallurgical expertise and polishing laboratories of Sigma and Materials Physics and Applications divisions; the spectroscopy laboratories of Materials Physics and Applications division; and the fabrication expertise of Prototype Fabrication division, which designed and machined the small and delicate samples critical in this experiment.

Funding: The work was funded by the Los Alamos Laboratory Directed Research and Development program, with support from the U.S. Department of Energy’s Office of Science U.S.-Japan Science and Technology Cooperation Program in High Energy Physics. It was performed, in part, at the Center for Integrated Nanotechnologies, a DOE Office of Science user facility operated jointly by Sandia and Los Alamos national laboratories.

LA-UR-25-29137