Rethinking a central mechanism for nuclear imaging

More efficiency, less dose are aims of new fabrication method

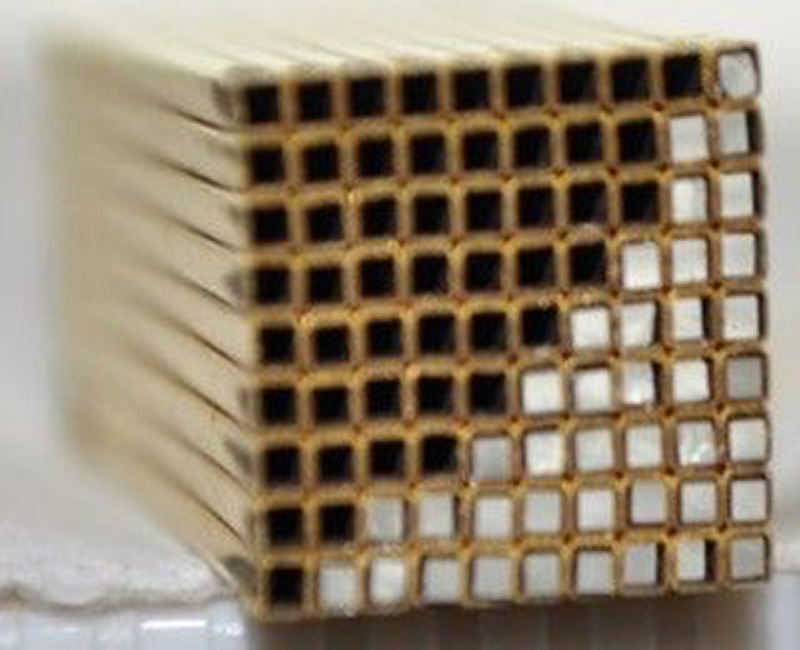

Higher-precision imaging at less radiation dose could benefit workers who use nuclear detection systems and medical patients who need CT or PET scans. Toward that end, Los Alamos scientists have developed a scalable method for fabricating high-resolution, high-Z scintillator grids using electroplating and hot isostatic pressing. Scintillators are crystal-based materials that absorb radiation and emit light, which photosensors use to create images.

See the recently published patent

Why this matters: Current grid fabrication methods rely on hazardous chemical etching and produce inconsistent structures that limit performance, scalability and safety. This new method addresses those limitations.

What they did: The team developed a way to manufacture “pixel separators,” or septa, for scintillator separation. The process uses bulk techniques that can be adapted to a wide range of materials, from high-Z options such as gold and rhenium to more cost-effective choices like bismuth.

How it works: Based on limited testing and theory, this invention appears to increase pixel-to-pixel efficiency by 30%, which could lead to higher-precision imaging technology at less radiation dose.

What’s next: This work focused on detectors for research imaging applications. More studies are needed to explore imaging quality and dose rates in other applications.

The inventors: Enkelada Dervishi-Whetham, Randy Edwards, Michael McBride, Dan Hooks

LA-UR-25-32001