| The Slitting Method for Residual Stress Measurement: : Mesocale stresses in Additive Manufactured Part |

Mesocale stresses in Additively Manufactured Ti-6Al-4V

Strantza, M., Vrancken, B., Prime, M. B., Truman, C., Rombouts, M., Brown, D. W., Guillaume, P., and Van Hemelrijck, D., 2019, "Directional and oscillating residual stress on the mesoscale in additively manufactured Ti-6Al-4V," Acta Materialia, 168, 299-308. https://doi.org/10.1016/j.actamat.2019.01.050. preprint (pdf).

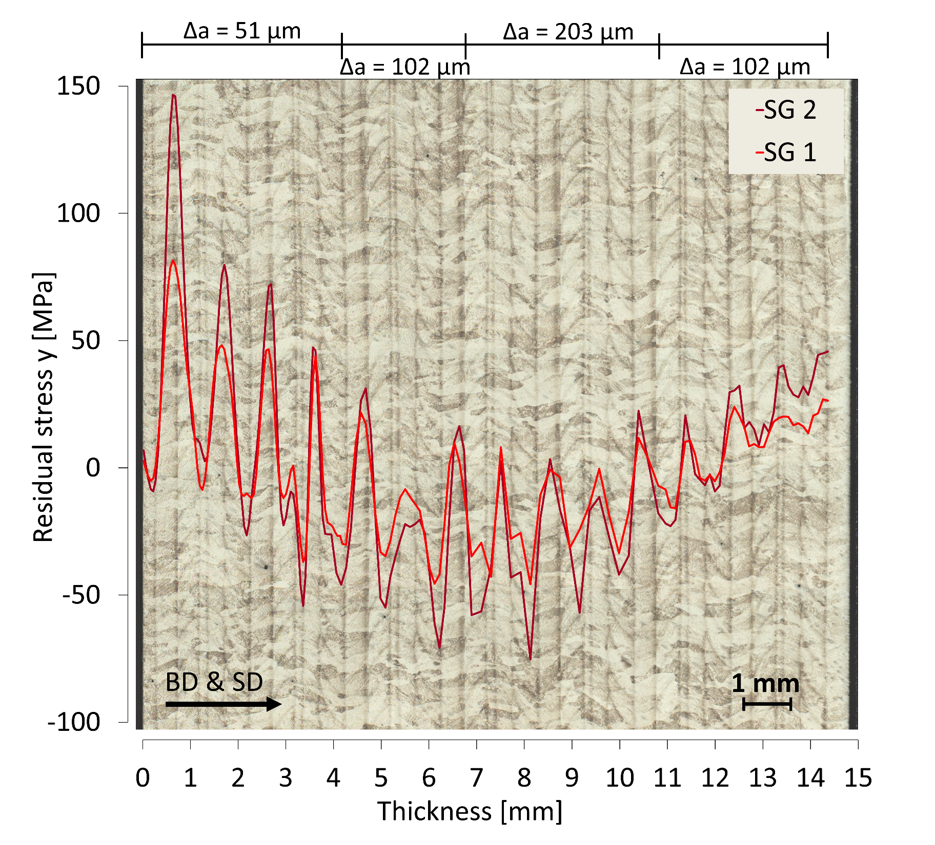

RESULTS: First ever measurement of layer to layer stress oscillations in AM part

|

|

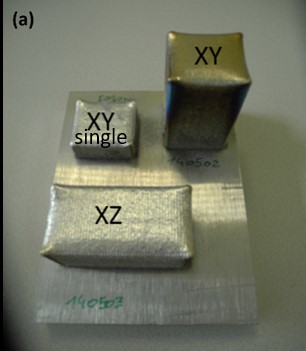

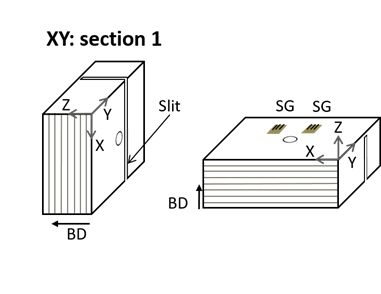

Titanium AM specimens:

|

|

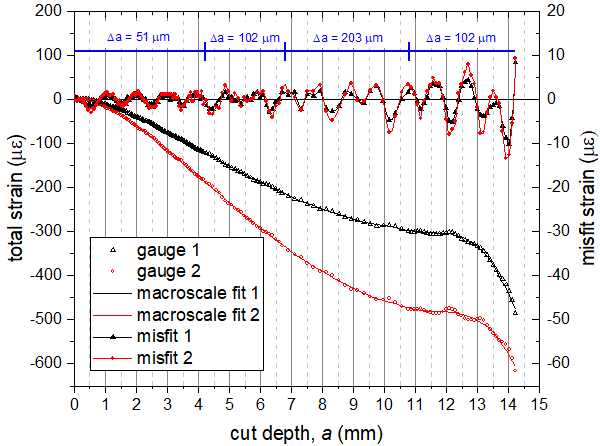

Most slit depth increments ever for a sliting measurement:

|

|

Strain data shows mesoscale:

|

|

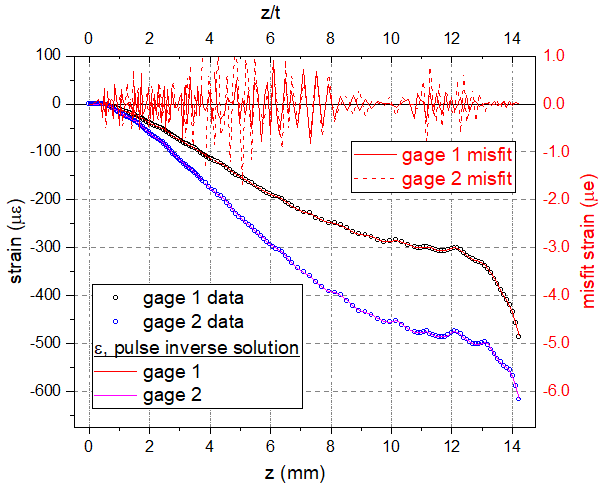

Only "pulse method" able to fit data:

|

|