Ultrasound Goes Underground

Using sound underground to see what can’t be seen

- Eleanor Hutterer, Editor

Using sound waves to create images is an idea that’s been around for nearly 80 years. Sound waves with a frequency higher than our ears can hear are called ultrasound, and, when bounced off of some obscured object, can relay information about the structure of that object.

The Department of Energy has funded a program called SubTER (Subsurface Technology and Engineering R&D), which facilitates collaborative research to address subsurface technical challenges. One such challenge is the reliable imaging of underground structures like oil wells. Simplistically, an oil well is a vertical steel pipe encased in cement and embedded in natural rock. Under the extreme pressure and heat involved in oil retrieval, a crack or deformation in any of these structures could cause the structure to fail catastrophically, so it’s important to monitor the wellbore’s integrity. Ultrasonic imagers use high-frequency sound waves to produce high-resolution images, but the waves cannot penetrate beyond the steel pipe, so the cement and rock strata can’t be monitored. In contrast, imagers operating at lower frequencies that can reach these outer layers produce only low-resolution images containing limited information.

As part of a SubTER multi-lab collaboration, Cristian Pantea, an acoustics physicist at Los Alamos, along with ultrasound scientist Vamshi Chillara and retired Lab Fellow Dipen Sinha, has invented a new kind of ultrasonic transducer, which, together with a receiver, makes up a new imaging tool. Called ACCObeam (acoustic collimated beam), it is the best of both worlds, having the penetration power of lower-frequency probes and producing high-quality images like higher-frequency probes.

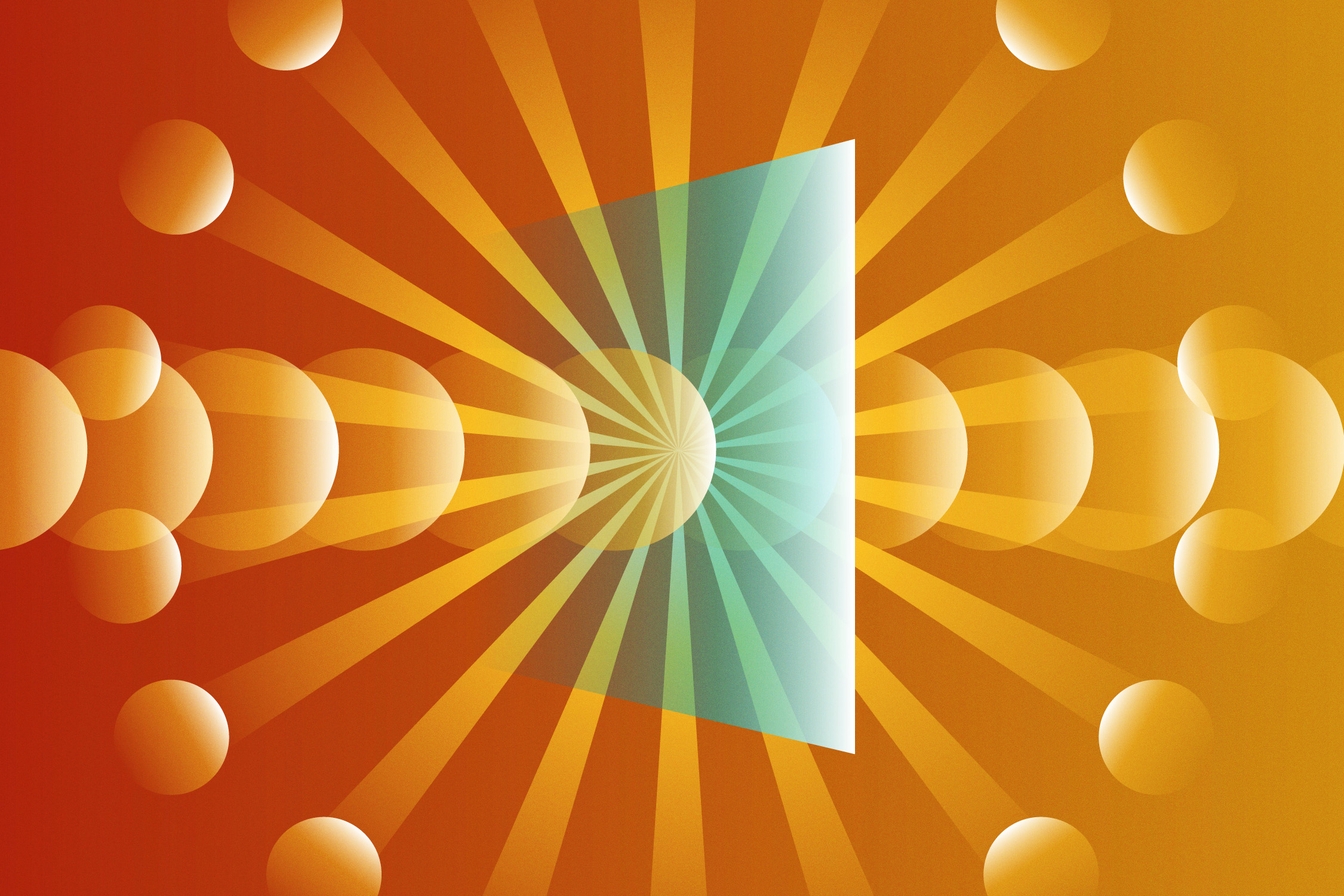

Ultrasound imaging transducers use piezoelectric materials to convert electricity into sound waves. But the sound waves these materials produce spread out considerably; they aren’t collimated. Collimation is the removal of nonparallel wave propagation so that the resultant beam spreads out minimally as it travels (a laser pointer is an example of collimated light). Early on, the ACCObeam team was looking for ways to reduce the nonparallel sound signals because they detract from and compete with the main signal. Through extensive experimentation and theoretical simulation, the scientists discovered that by laterally clamping their piezoelectric disc (as shown), they could collimate their sound waves. The clamp solved another, more practical problem too: how to physically attach the transducer to the end of the probe.

Since that breakthrough, Pantea, Chillara, and Sinha have continued to experiment, theorize, and simulate, developing a detailed understanding of the physics behind sound collimation so they can fine-tune and control their ultrasound signals. ACCObeam is powerful and inexpensive compared to other options available. It’s also much faster, imaging in less than a day what used to take a week. Pantea, Chillara, and Sinha are still perfecting the design, but they are already thinking about other ways this technology can be used. Bomb detection, long-range undersea communication, medical imaging, and the wireless powering of implanted medical devices are a few places where they can see ACCObeam shining.