LiDAR at LANSCE supports major modernization

Capturing the present to plan for the future.

- Lisa Cantrup, Science Writer

Download a print-friendly version of this article.

One of the Lab’s most historically significant and technically complex facilities, the Los Alamos Neutron Science Center (LANSCE), is getting an upgrade. As part of the planning for this intensive project, a small team of engineers is using modern scientific imaging methods to map out every detail and ensure the project goes smoothly.

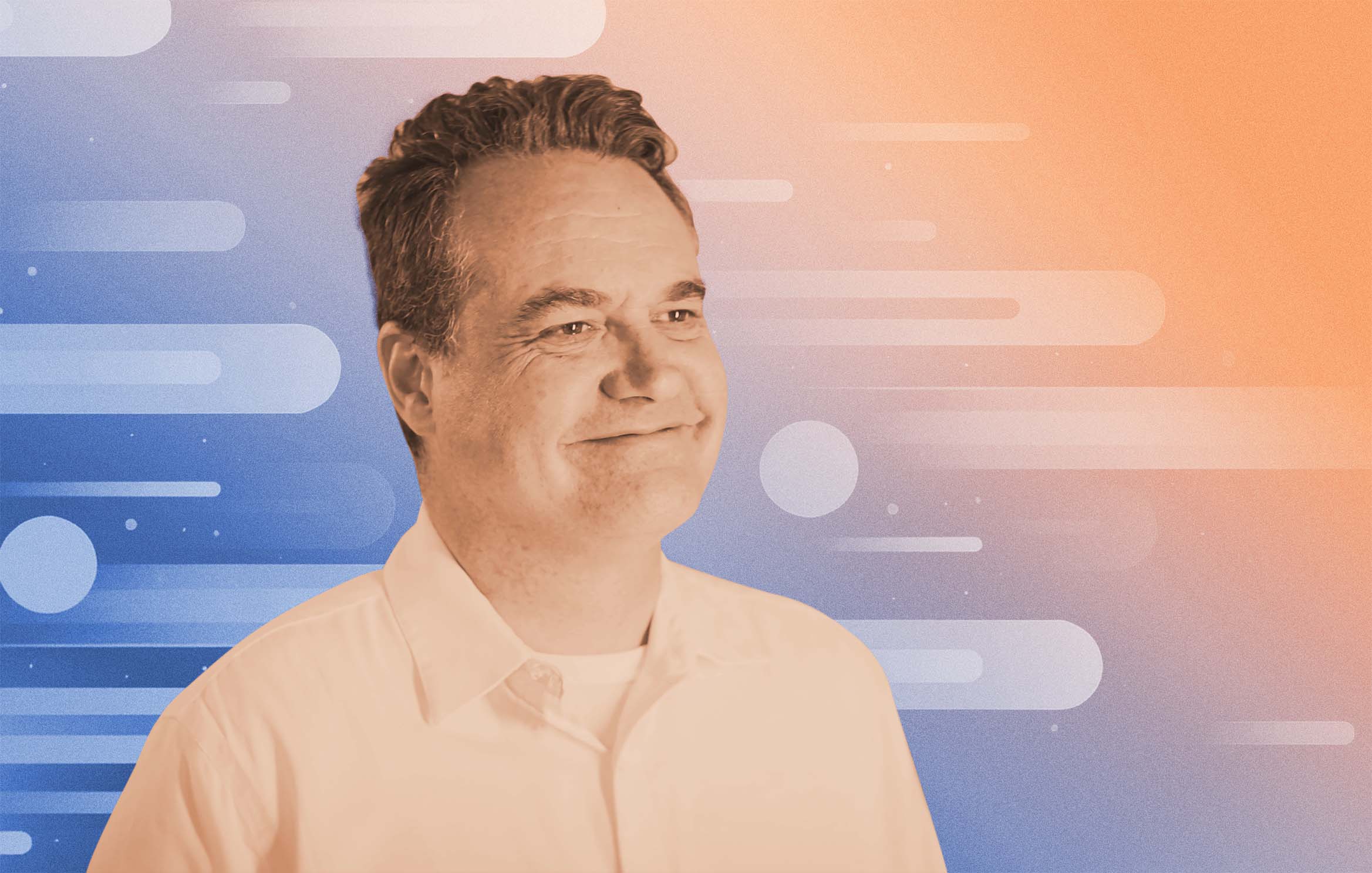

The LANSCE Accelerator Modernization Project (LAMP) is an ongoing effort to modernize the massive particle accelerator at LANSCE. Two members of the Laboratory’s Engineering Services team, engineer Kenny Feller and drafter Martha Gomez, recently conducted a detailed 3D scan of the front end of the LANSCE beamline, where protons are produced and begin their acceleration journey. The team’s work shows how in-house tools and expertise can support mission needs in a timely, cost-effective way.

Long-term vision for LANSCE

LANSCE has been in operation since 1972, powered by an 800 megaelectron-volt proton accelerator that simultaneously supports five experimental areas. LAMP aims to modernize key front-end components of the accelerator to support continued operation through 2050. That includes replacing aging infrastructure such as the original ion sources—two huge Cockcroft-Walton generators—and the drift tube linear accelerator, which are well past their expected lifespans.

To plan this work safely and efficiently, accurate, up-to-date facility information is essential. The job of producing a 3D scan was originally intended for a subcontractor, but schedule constraints made that route unworkable. That’s where Feller and Gomez came in.

Thanks to the Laboratory’s investment in modern tools and training, Feller and Gomez were able to step up and complete the work themselves, keeping the project on track.

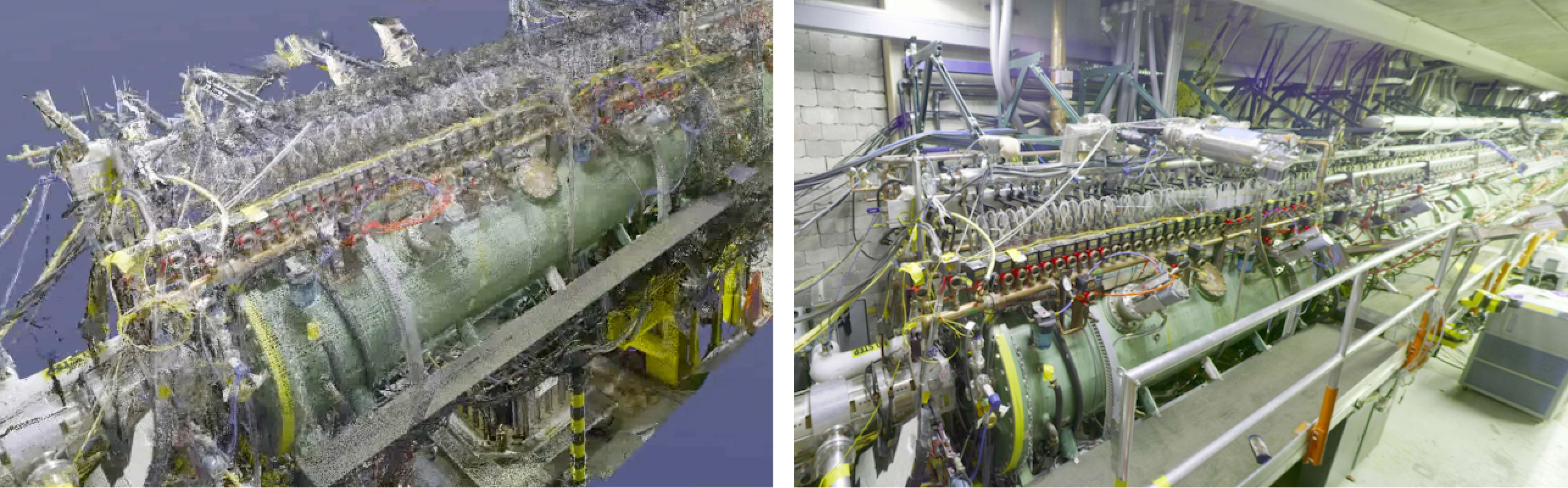

Using the Lab’s own LiDAR equipment, the team completed a full scan of the front end of the beamline. LiDAR—short for light detection and ranging—is a remote sensing method that uses laser pulses to measure distances and create highly detailed 3D representations of physical environments. It’s a powerful imaging technique used in everything from self-driving cars to archaeology, but in this case, it’s helping to modernize the proton accelerator.

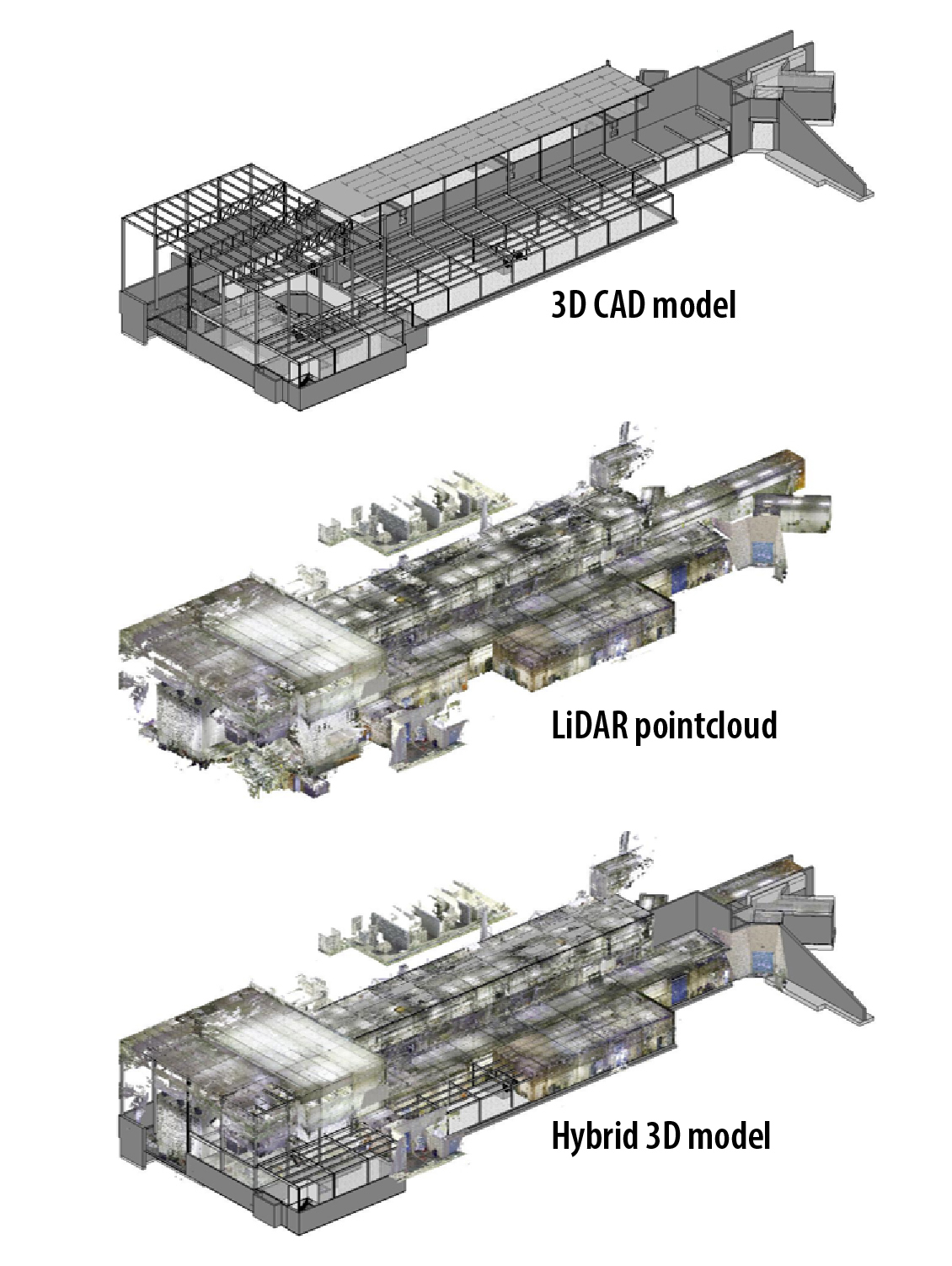

The scanned LiDAR data was turned into a 3D point cloud, or system of coordinates representing all scanned surfaces, which the team used to validate an existing Revit model and support planning for upcoming work under LAMP. Revit is a building information management (BIM) software tool that combines 3D models with other types of information, like quantities, schedules, and design changes. Using LiDAR data to validate and update the model provides a clearer, more accurate view of the space, supporting design decisions and reducing the likelihood of field errors.

“A 3D model gives us the ability to understand the space clearly before work begins,” Feller said. “That kind of visibility helps us plan safer, smarter projects.”

LAMP Technical Director, Gregory E. Dale, emphasized the value of the LiDAR scan in project planning. “We were all pleased and excited to see the laser scan results of the accelerator tunnels,” he says, “it’s almost like giving everyone x-ray vision during the planning process.”

Dale adds, “The laser scan is also very helpful for our design reviews, especially when the review happens when the machine is running and the beamlines are inaccessible.”

The scanning effort supports broader goals around safety and work planning, including more effective integrated work management. While adopting point cloud and BIM workflows represents a shift in approach, it’s ultimately about making sure the digital version of a facility matches the physical one, in both form and function.

This technology also enables views that traditional methods can’t offer. You can digitally chop off roofs, look underneath floors, and view equipment or piping from multiple angles—even from underground. That’s especially valuable in tight spaces like the beamline, where physical access is limited.

“It’s just so visual. It’s like being able to hold the room in your hands. And honestly, it’s pretty darn accurate.”

It also provides better planning flexibility. Because LANSCE is only accessible for hands-on maintenance during a limited annual three-month shutdown window, having detailed digital models means planning can happen year-round, even while the facility is in operation.

Engineers and planners can take virtual measurements, estimate materials, and explore the environment remotely.

“How tall is the ceiling? How much cable do we need? You can answer those questions from your desk,” Feller explained. “It’s a smart way to reduce uncertainty without ever stepping foot in the space.”

Team LiDAR

Feller, a structural engineer who has been at the Lab since 1991, joined the facility team in 2021 and brought more than three decades of experience to LANSCE. He began exploring LiDAR and BIM tools for infrastructure planning in 2023, drawn to their potential for improving accuracy and safety.

Gomez, who joined the Lab two years ago as a drafter, had previous field experience with LiDAR scanning from working in Texas refineries. When Feller began exploring the technique as a solution at LANSCE, Gomez told him, “If you get the equipment, I know how to use it.” Their skill sets—Feller with Revit and modeling, Gomez with point cloud scanning—created a balanced, hands-on team that could quickly put the tools to use.

Together, they’ve helped jumpstart a broader effort at LANSCE to model key infrastructure areas. Beyond the beamline scan, their work supports digital models of downstream facilities like the Proton Storage Ring, the Lujan Neutron Scattering Center, and the Proton Radiography Facility dome. Even just capturing the dome perimeter with LiDAR yielded valuable insights that weren’t available in legacy documentation.

In one of the neutron experimental areas, scanning supported a major electrical panel replacement. With beam operations scheduled to resume, time was short. Feller and Gomez scanned the space before it became inaccessible, and Gomez created a floorplan that reflected actual field conditions. “That didn’t exist before, not accurately. We had old CAD files, but they weren’t reliable for this kind of planning,” Feller said, referring to outdated computer-aided design files.

Using the new model, the team was able to place new panels virtually, then share the updated plans with contractors for bidding and execution. That information became part of the technical baseline for the area, creating a shared source of truth across teams.

“It’s just so visual. It’s like being able to hold the room in your hands,” Gomez said. “It minimized the time we had to spend onsite in tight or potentially hazardous spaces. And honestly, it’s pretty darn accurate.”

Having the point cloud embedded in existing CAD files helped the team plan in ways that would have been difficult or impossible using traditional documentation. “The model reflected reality. That was the difference,” Feller added.

Building a baseline

This work also supports a larger goal: improving the technical baseline for Lab facilities. Configuration management isn't just about drawings; It’s about having a digital footprint that reflects what’s in the field both spatially and informationally. That includes when equipment was installed, who manufactured it, and when it might need to be replaced.

Although traditional CAD drawings are still common, they’re limited. CAD is 2D and usually lacks the detail needed for accurate decision-making. By integrating LiDAR data into BIM workflows, the team is helping the Laboratory move toward a more complete digital view of its infrastructure.

“CAD is useful, but it doesn’t capture the full picture,” says Feller. “This approach helps us manage the space more effectively over time.”

There are still gaps, especially around Revit skills in mechanical, electrical, and plumbing modeling. “We had to get creative. We didn’t have Revit-trained mechanical modelers, so we had to improvise with the skills we did have and lean hard on teamwork,” says Feller. “This kind of work really depends on people being flexible and willing to learn as we go.” But this project shows what’s possible and points the way for future development.

Los Alamos is modernizing not only its buildings but how it delivers on its national security mission.

This LiDAR method isn’t just about LANSCE. It’s an example of how digital tools can be applied to improve infrastructure management across the Lab. From legacy facilities to new construction, laser scanning and BIM provide a consistent way to accurately capture conditions, improve safety, and reduce costly rework.

“This is exactly the kind of model we can apply across the Lab,” says Rob Swickley, deputy division leader of Engineering Services. “It’s scalable, efficient, and supports good stewardship of our infrastructure.”

Feller and Gomez’s work is helping the Lab move toward a more integrated and digital approach to facility management. As projects like LAMP continue, the need for current, accessible, and accurate facility information will only grow.

This work also reflects the broader priorities of the Department of Energy and the National Nuclear Security Administration, including digital engineering, lifecycle asset management, and mission readiness through infrastructure resilience. By aligning with these goals, Los Alamos is modernizing not only its buildings but how it delivers on its national security mission.

“Imagine having a digital twin for every legacy structure at the Lab, where any engineer can walk a site virtually, measure clearances, check spec sheets, and plan safe access, all from their desktop,” said Bruce Gunderson, BIM Manager with Engineering Services.

By investing in the right tools and fostering internal expertise, Los Alamos is creating stronger foundations, both digital and physical, for the future.

People also ask

- What is LiDAR scanning? LiDAR (light detection and ranging) is a remote sensing method that bounces laser light off surfaces and measures the time it takes to come back. Like RADAR uses radio waves, LiDAR uses light. The time it takes the light to return gives the distance of a point on the measured surface. Taking repeated measurements creates a cloud of points, from which emerges a detailed 3D representation of the scanned area.

- What is a point cloud? A point cloud is a collection of data points that inhabit a three-dimensional space, each with an x, y, and z coordinate. Generated by methods like LiDAR, the point cloud is used for highly detailed 3D modeling.