Engineering against the clock

Photos from Los Alamos National Laboratory’s National Security Research Center shed light on the monumental effort behind the Trinity test—the world’s first nuclear detonation.

- Emily Seyl, Communications Specialist, National Security Research Center

The images and text in this article are excerpted from Trinity: An Illustrated History of the World’s First Atomic Test. The forthcoming book from Los Alamos National Laboratory’s National Security Research Center includes a foreword by author and historian James Kunetka and showcases more than 400 photographs. In addition to displaying what you see here, the book explores the aftermath and legacy of the world’s first nuclear test.

Weeks before the world would learn of the atomic bomb, upon its wartime use against Japan, a team of scientists and military personnel detonated the world’s first nuclear device on a remote bombing range in south-central New Mexico, at a site codenamed Trinity. What was painstakingly orchestrated to be a secret moment lit up the predawn sky for hundreds of miles as the explosion shattered projections of its magnitude. Both a military proof-test and an elaborate, well-documented science experiment, the July 16, 1945, trial shot brought under the control of humankind a new fire—the energy of the atom.

Through the first half of 1944, the prototype device that would be detonated in the Trinity test was still in the early stages of development at Project Y (what is today Los Alamos National Laboratory). According to its basic design, a small, central sphere of fissile material would be compressed by a much larger, outer sphere of conventional explosives to form a supercritical mass inside the weapon, generating a nuclear explosion. For the weapon’s creators, orchestrating this series of events meant overcoming significant engineering challenges through an exhaustive process of modeling and trial and error. Only a full-scale shot of a completed weapon could reveal whether all possible flaws had been discovered and resolved; scientists could not otherwise rule out the possibility of a fizzle—a stunted, low-yield detonation.

However, conducting test shots would require expending fissile material, which was not yet available from either the plutonium or uranium production facilities. Dedicating the first batch of usable nuclear fuel to test devices might therefore delay the schedule for completed, deliverable weapons. Despite this drawback, it was a strategic imperative that if a nuclear bomb was going to fail, it do so in secrecy. Thus, as the implosion method gained traction in the early part of 1944, General Leslie R. Groves, the leader of the Manhattan Project, agreed tentatively to the full-scale trial shot.

Prompted by fuel scarcity and low confidence in the implosion design, Groves placed a condition on the operation: scientists could move forward with planning, but the test must be conducted in such a way that if the device failed to produce a nuclear explosion, they could retrieve the remnants and reuse its unfissioned nuclear material. Accepting this requirement—which in some ways would come to rival the challenges of building the bomb itself—laboratory director J. Robert Oppenheimer appointed physicist Kenneth Bainbridge to lead a new group that would begin working on the various facets of a test shot. He codenamed the operation Project Trinity. “Why I chose the name is not clear,” Oppenheimer later wrote, recalling only that a line from John Donne’s Holy Sonnets was in his mind at the time: “Batter my heart, three person’d God.”

In addition to identifying and securing a test location and building out the necessary infrastructure, Bainbridge and his group were to ensure a complete photographic record was made of the attempted detonation, along with comprehensive measurements of its effects. If the implosion device worked, the information gained would be invaluable to the army and the field of nuclear science; if it didn’t, scientists could hopefully determine from the records what went wrong and try again.

While many decisions loomed for the newly instated test director, the burden of meeting Groves’s condition fell to R. W. Carlson, a pioneer in concrete technology. His challenge was to devise a way of containing the test device’s large conventional explosion to a small area so that if the test device was a dud—meaning the conventional explosives component detonated but failed to trigger a nuclear detonation—the fissile material could be salvaged. Putting forth an extraordinary effort to achieve this in parallel with other test planning, Carlson’s group ultimately commissioned a super-sized detonation chamber, dubbed “Jumbo,” into which 12 million wartime dollars and half a million pounds of steel were invested.

Development of an implosion device and plans for testing it proceeded mostly in a two-steps-forward, one-step-back manner. Then, an unexpected turn of events catapulted both to new importance within the nuclear program: Project Y’s gun-type method for a weapon, an alternative to implosion that was much preferred for its simplicity and was significantly further along in development, was determined to be compatible only with uranium—not plutonium. At this juncture, a billion dollars had been invested in synthesizing plutonium, which was suddenly unusable unless a viable implosion-type weapon could be developed. Additionally, the Manhattan Project’s uranium enrichment facilities were riddled with technical difficulties; coupled with the low fuel efficiency inherent to the gun-type design, this meant there would not be enough uranium available to quickly replicate uranium-fueled combat units. If the United States was to firmly establish a nuclear arsenal, and make use of its investment in plutonium, it seemed it would have to rely upon the straggling implosion technique.

The new circumstances not only redefined the significance of the forthcoming implosion test but also spurred Oppenheimer to reorganize personnel and activities at the laboratory. Study of the Gadget, as the first full-scale implosion device has come to be called (all weapons under development were referred to as “gadgets”), was previously led by a group housed within the Ordnance Division. That division became responsible for completion of a uranium-fueled gun-type weapon, codenamed Little Boy, while two entirely new divisions were created to fast-track the design and fabrication of a plutonium-fueled implosion Gadget. It was August 1944, just short of a year and a half into the laboratory’s existence.

Groves reported to U.S. Army Chief of Staff General George C. Marshall that a deliverable implosion weapon (codenamed Fat Man) could be available in the second quarter of 1945, provided the test shot of the Gadget was satisfactory. For the first Little Boy unit, with uranium fuel, he estimated delivery in August 1945. Scientists rushed throughout the remainder of the year and into the next to develop the two very different weapons, as the laboratory prepared simultaneously for the Manhattan Project’s scientific moment of truth: a secret, full-scale field test staged in a lonely desert basin that would reveal either a complete failure, a fizzle, or the world’s first nuclear explosion.

The images and text that follow trace the execution of the Trinity test through carefully restored images housed for 80 years in the archives at Los Alamos National Laboratory.

Building the site

As the first order of business, a field headquarters was established about 10 miles southwest of ground zero at a cluster of ranch buildings, inhabited before the army’s 1942 arrival by rancher Dave McDonald and his uncle, Ross McDonald. The original structures were quickly expanded into a base camp that would house the personnel setting up infrastructure and diagnostic equipment for the test shot.

The 28-mile Pope Road, shown running east (toward ground zero), was built to bring in Jumbo and other large deliveries from the nearest rail siding.

Many base camp buildings, such as the barracks and the mess hall, were brought in from campsites of the defunct Civilian Conservation Corps. Other structures, such as a latrine, were built up from new, poured-concrete foundations. All facilities had one thing in common: they were completed and outfitted with the utmost efficiency and cost savings. “Luxuries” were disallowed by Groves.

Jumbo

As confidence increased in the implosion method and plutonium production rates improved, interest in the scientific value of the test shot came to supersede the initially paramount concerns about a fizzle. If the Gadget detonated within the thick, steel walls of Jumbo, the behavior of the nuclear explosion, even as it vaporized the containment vessel, would be so skewed as to render the results of any experiments mostly useless.

So it was that by the time of its arrival—and, in fact, its departure from the manufacturer in Ohio—Jumbo had been relieved of its role in the Trinity test. Oppenheimer instructed in March 1945 that all preparations should assume the detonation chamber would not be used. Though Bainbridge wrote that Jumbo remained “a silent partner in all our plans,” the vessel was placed not at ground zero but 800 yards to the northwest, joining a ring of some of the closest-range instrument bunkers. Unless the Gadget hit a serious design hurdle, or it fizzled and a second test was needed, the weighty investment in failure would loom quietly from the sidelines as history unfolded around it.

100-ton test

The months of intense preparation for the test of the Gadget were punctuated by a rehearsal shot that took place in early May. Kenneth Bainbridge had lobbied Oppenheimer a year before to approve what became known as the 100-ton test—a scaled-down detonation meant to simulate that of the Gadget, using conventional explosives laced with radioactive material. As intended, the test brought into focus the many potential missteps that could affect the Trinity schedule, the detonation itself, and the success of diagnostic instruments.

While the tower was built by civilian contractors, the explosives were handled by servicemen from the Special Engineer Detachment and the Military Police.

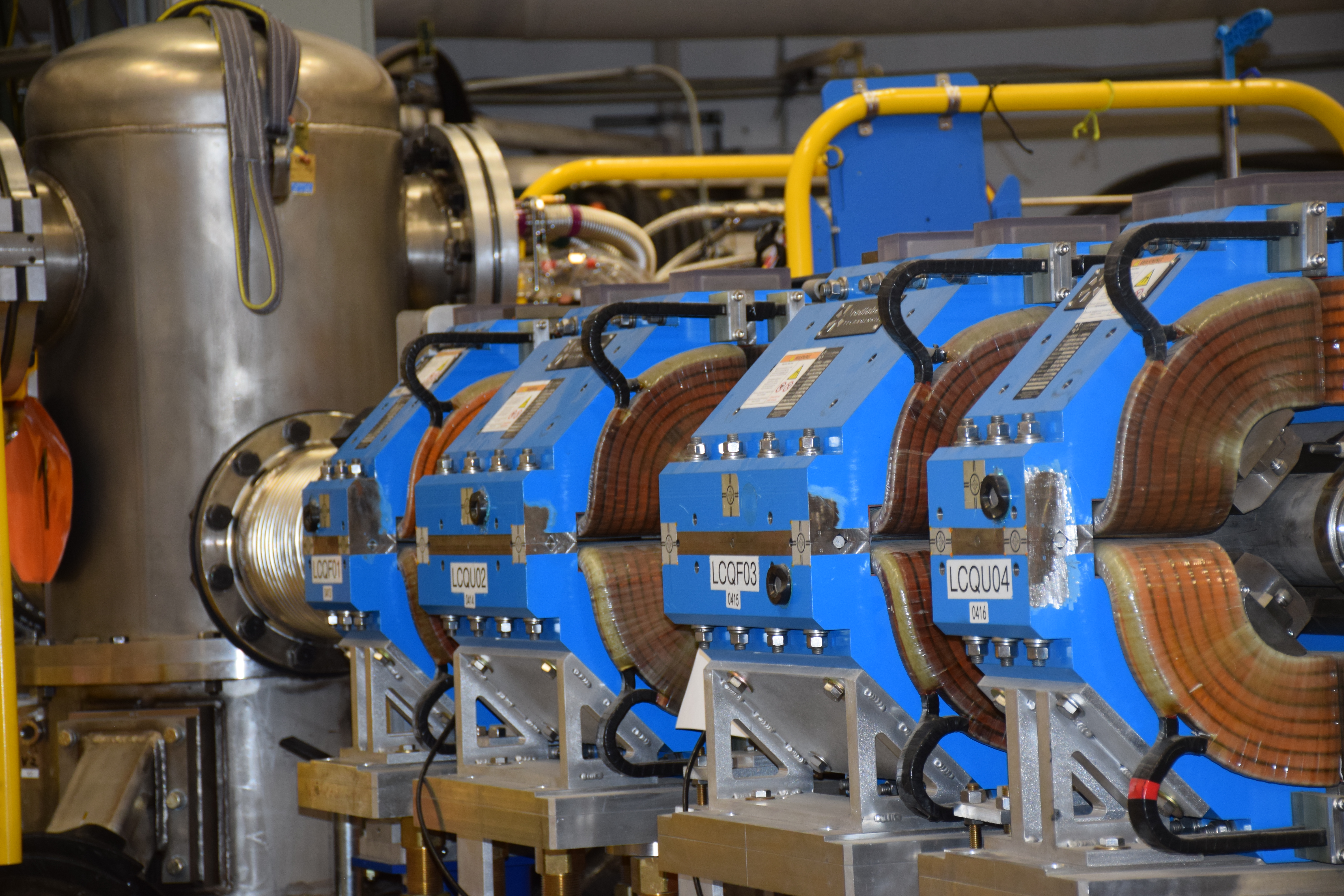

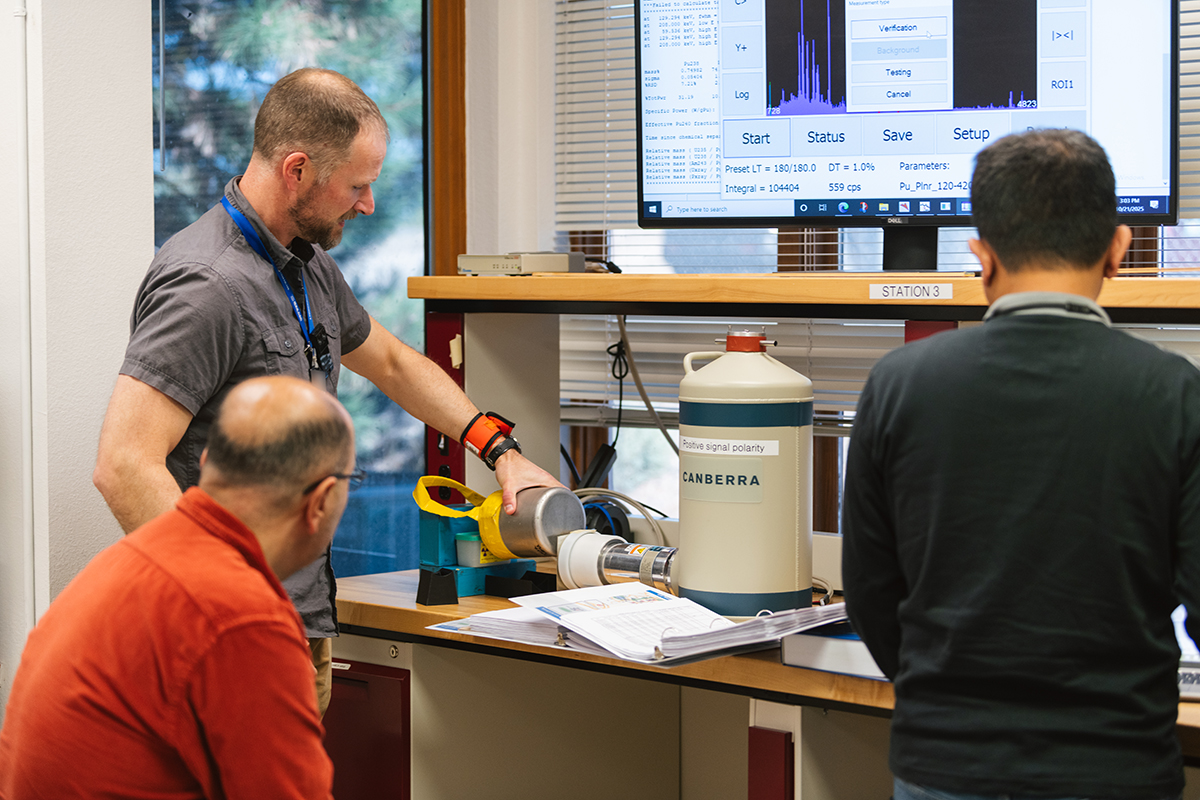

Diagnostics

The pressure of the shock wave, indicative of its destructive force, was of particular interest because it would help scientists determine for the military the ideal height at which to detonate the weapon. One device used to obtain this essential measurement was the impulse gauge, configured to squirt a pressure-dependent amount of water out of a piston as the shock wave passed by. Instead of transmitting a signal, which would be vulnerable to interference from radiation, these fully mechanical devices (some placed as little as 350 yards from the blast) etched pressure readings onto a built-in disc spun by a repurposed windshield-wiper motor. Just as cameras were set up to account for different possible lighting conditions, the impulse gauges were set to respond to a wide range of pressures, from 2.5 to 150 pounds per square inch.

The shock wave’s speed was an important marker as well. In simple terms, a shock wave is a sound wave traveling and vibrating faster than the speed of sound. Exactly how much faster depends on the yield of the blast: as yield increases, the speed of the shock wave increases proportionately. To take advantage of this known relationship, as a means of calculating the Gadget’s energy yield, scientists set up what were called excess velocity experiments. In one elaborate version, an explosive called pentolite—which produces a shock wave of known velocity—was to be detonated near ground zero a few seconds ahead of the Gadget. Dangling plywood boxes containing microphones would register the arrival of the pentolite wave (providing a baseline) and the subsequent arrival of the Gadget’s shock wave—enabling scientists to deduce the unknown velocity by comparison.

While base camp materialized at a record pace, much work remained to be done elsewhere at the Trinity site. The test plans called for small and large bunkers, various towers (including one for erecting Jumbo), and always-evolving infrastructure to support an extensive program of diagnostics. As islands of activity began to dot the empty basin, workers graded dirt and gravel roadways and laid a sprawling network of power lines and data cables to enable communication and travel between instrument stations, personnel shelters, ground zero, and base camp. The jeep above, with a spool attachment, was used to run long spans of cable.

Three main shelters were established 10,000 yards (about five-and-a-half miles) from ground zero—one each to the north, south, and west. These would house diagnostic instruments and personnel during the test shot.

Eager to learn everything possible about the performance of the test device, scientists and engineers were consumed from dawn to dusk with readying cameras and other diagnostic instrumentation to track the effects of the blast from detonation to dissipation.

Countdown

In the early morning hours of July 16, poor weather threatened to cause a delay, if not a full postponement, of the test shot as radiation monitors, the seismograph deployment team, and more than 400 additional spectators—including laboratory staff, military personnel, and government officials—began to convene at their designated observation points. Scattered among them, noteworthy witnesses included three doctors, an embedded reporter from The New York Times, and two men—Klaus Fuchs and Oscar Seborer—who would decades later be confirmed as spies for the Soviet Union.

Despite strict security measures in place, Groves viewed the final waiting period—and every minute of delay—as an opportunity for some nefarious individual to tamper with the Gadget. Thus, a group including Donald Hornig (above) took shifts guarding the all-important device atop the tower. Although the 100-foot structure was properly grounded, Hornig, taking the last shift, remained understandably anxious as lightning bolts illuminated the desert sky.

At 3:30 a.m., the rain finally began to clear. The storm clouds were forecast to scatter shortly before dawn. Zero time, originally 4 a.m., had already been pushed back an hour and was now reset again to 5:30—when the first light of day would be peeking over the horizon.

“The damned thing worked.” —physicist Norris Bradbury

From his position near base camp, southwest of the explosion, technician Jack Aeby took a series of photos by hand when the countdown reached zero. Aeby, a member of the Special Engineer Detachment and an amateur photographer, received permission from his group leader Emilio Segré to document the test with his personal camera, a Perfex 44. He captured what is now the only quality, color image of the Trinity test.

When the brightness faded enough for witnesses to make out ground zero, they saw a wall of dust rise up around a brilliant, shape-shifting, multi-colored ball of flames—forming a fiery cloud that shot into the sky atop a twisting stream of debris. ★