Uncommon knowledge

Nuclear facilities engineers prepare the Plutonium Facility for its national security mission.

- Alexa Henry, Communications specialist

Originally opened in 1978 as a research and development (R&D) center, Los Alamos National Laboratory’s Plutonium Facility (PF-4) is undergoing a major, multiyear infrastructure upgrade. The goal: to establish the capacity to produce at least 30 stockpile-ready plutonium pits—cores for nuclear weapons—each year. Transitioning PF-4 from an R&D site to a full-scale production facility requires the precision, dedication, and deep expertise of a highly specialized engineering team.

Nearly 200 nuclear facilities engineers and technical support staff are responsible for maintaining and operating the 233,000-square-foot facility 24/7, year-round—both during the ongoing renovations and into the future as pit production ramps up. Additionally, they maintain other nuclear facilities that are vital to the success of PF-4.

“We’re trying to take an older Porsche and turn it into a race car,” says Sid Ellis, a nuclear facilities engineer with the Laboratory’s Plutonium Facilities Engineering (PFE) division.

“Except we’re doing it while driving down the highway at 75 miles per hour—and doing it safely,” adds Robert Hayward, a group leader in the PFE division.

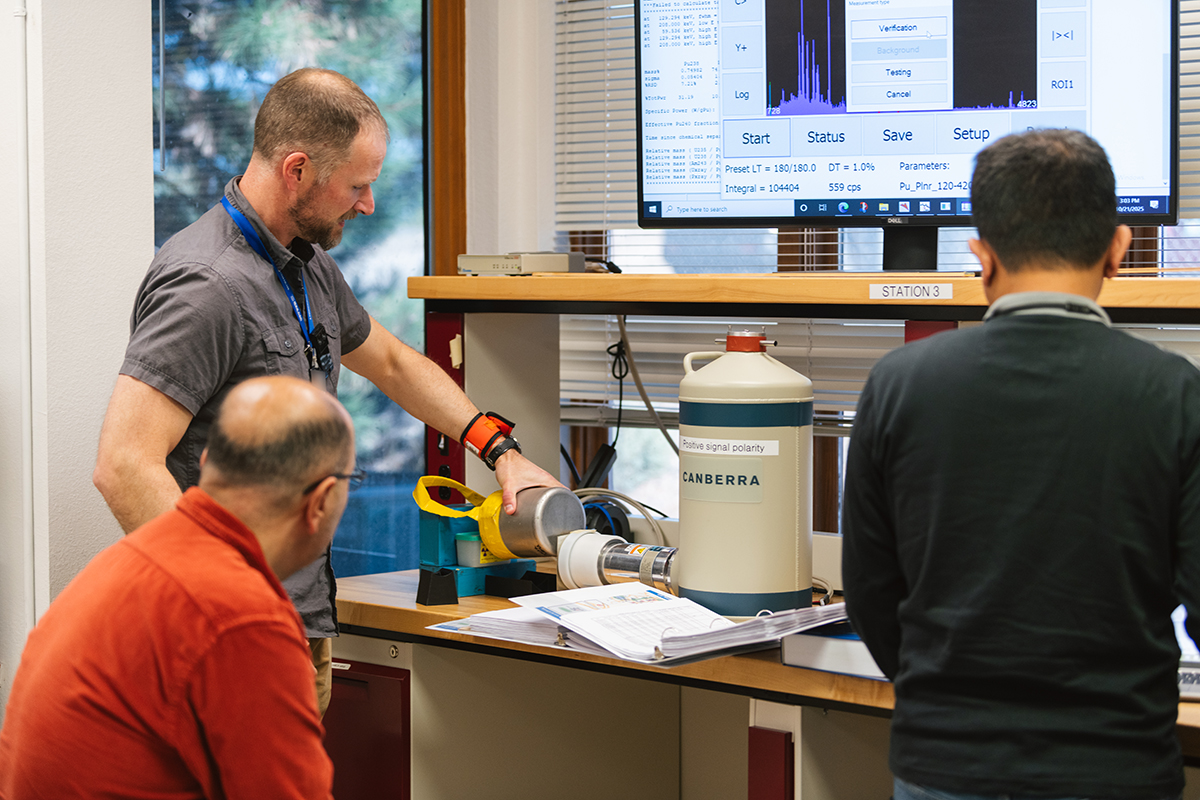

Nuclear facilities engineers come from a variety of disciplines—chemical, civil, structural, mechanical, and more. “Our engineers often take on work that extends well beyond the scope of a traditional engineering degree,” explains PFE Division Leader Jorge Ruiznavarro, who notes that nuclear facilities engineers complete a rigorous qualification program. “Much of their work involves specialized tasks, such as overseeing nuclear safety systems, installing of one-of-a-kind programmatic equipment, or navigating complex compliance requirements.”

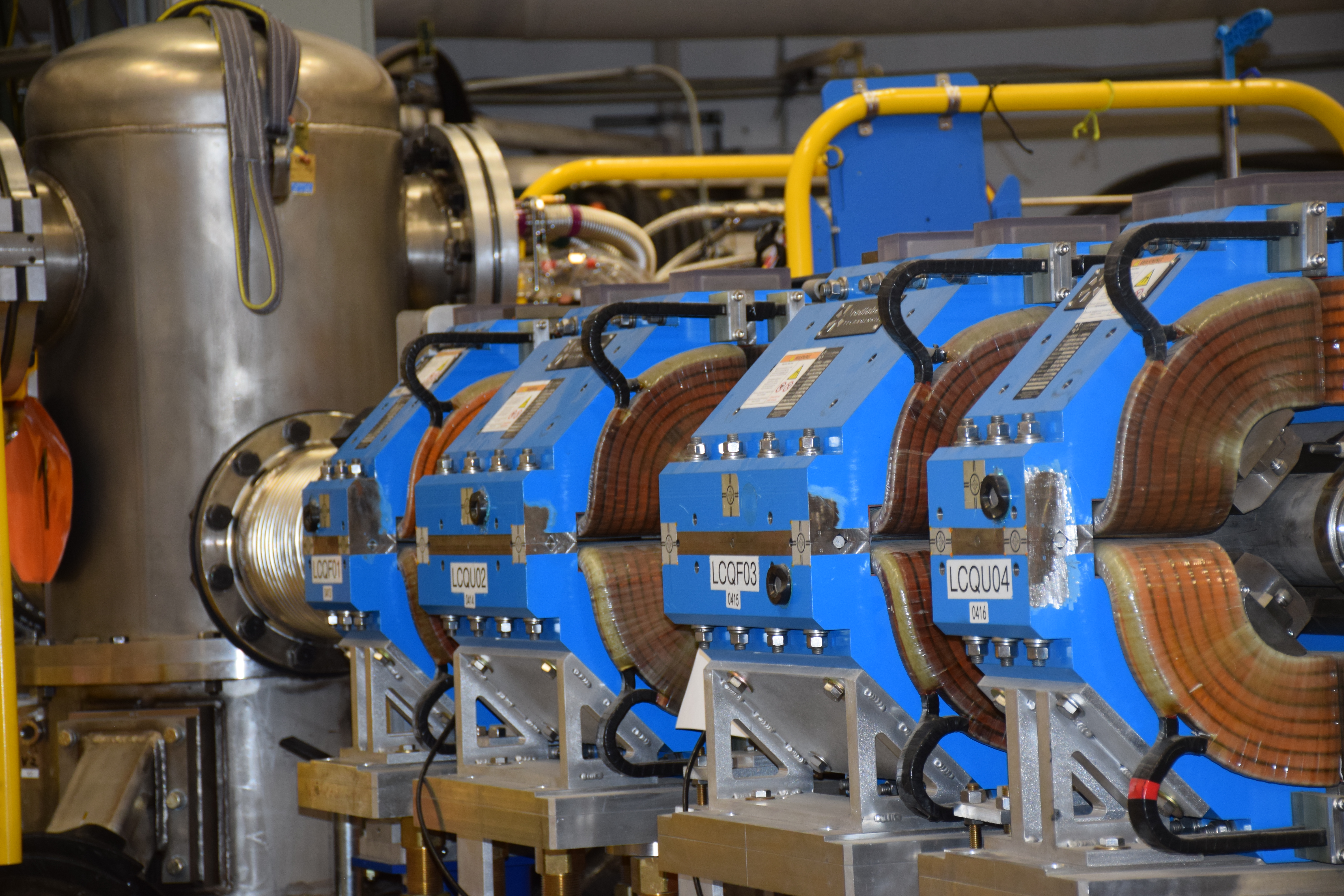

The PFE division oversees everything from large industrial systems—such as boilers, electrical switchgear, and fire suppression pumps—to highly specialized safety equipment such as gloveboxes, which are essential for the safe handling of plutonium.

“This isn’t the kind of job where you make an immediate impact,” Ellis says. “It’s not just about what you learned in college—it’s about learning the systems, understanding the risks, and applying that knowledge over time.”

Facilities engineers lead and support the design and implementation of complex equipment and infrastructure projects. But no matter their specific focus, one priority is shared across the board: safety.

Many engineers, like Ellis and Hayward, also serve as cognizant system engineers, meaning they receive additional qualifications to oversee critical safety systems that protect workers, the public, and the environment from nuclear and industrial hazards.

“Our job is to look at a design and ask, ‘Is this safe enough? Will it protect the worker?’” says nuclear facilities engineer Renee Mondragon, who is also a cognizant system engineer with PFE. “That’s what gloveboxes do—they protect workers from the materials inside, and it’s my job to make sure they’re doing exactly that.”

“We are the organization that’s protecting your families,” emphasizes Dann Alison, recently retired deputy division leader for PFE. “We work hand-in-hand with pit production, balancing mission success with the highest commitment to safety. Yes, we’re here for the mission—but more importantly, we’re here to keep people safe.” ★