Mining with amino acids

Los Alamos scientists aim to boost rare earth element supply through protein engineering.

- Ian Laird, Communications specialist

Rare earth elements (REEs)—a group of 17 elements including the lanthanides, scandium, and yttrium—are essential to technologies ranging from smartphones and electric vehicles to wind turbines and defense systems.

“REEs are used in pretty much everything,” says Ramesh Jha, a synthetic biologist at Los Alamos National Laboratory. “Naming just a few applications almost downplays their importance.”

Despite the name, REEs aren’t particularly rare—but they are difficult to isolate from other materials. Conventional separation uses solvent-based extraction, a multi-stage process that produces significant toxic waste and is inefficient for low-grade ores.

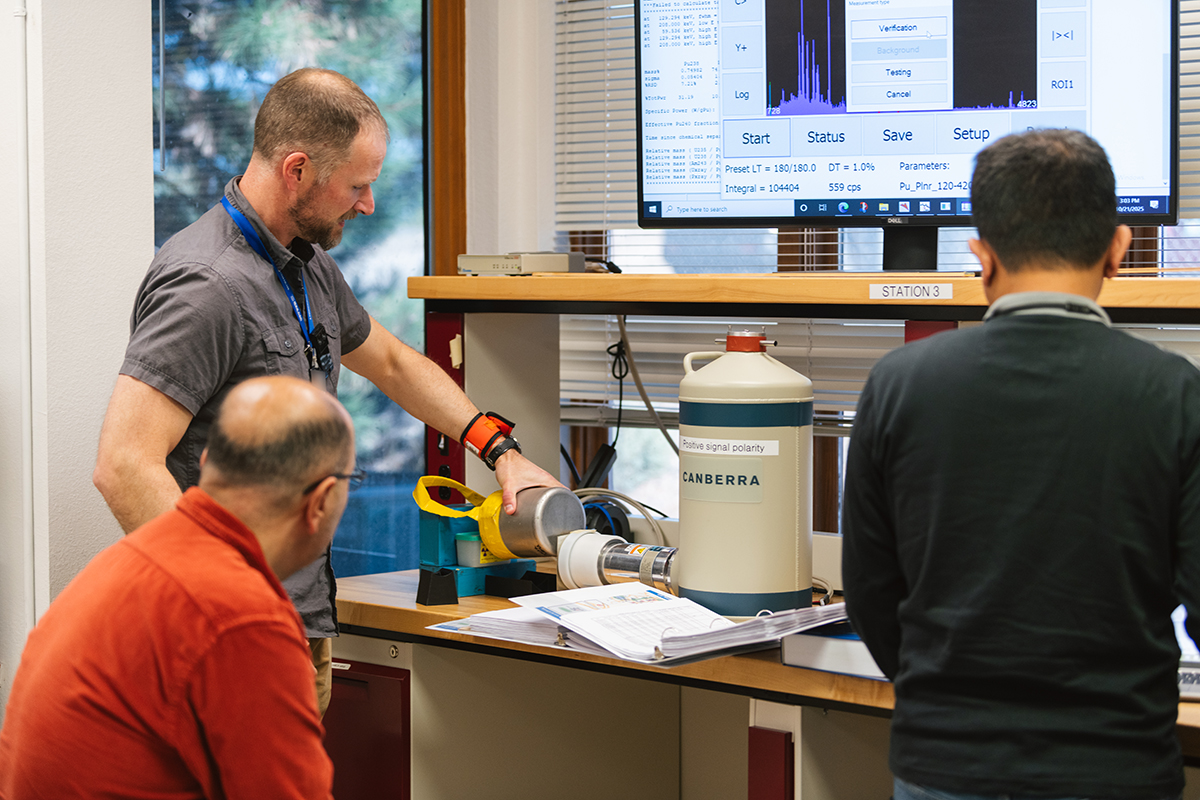

“Solvent extraction isn’t economical for low-concentration feedstocks,” explains analytical chemist Nilusha Sudasinghe.

About 80 percent of REEs in the United States are imported. The other 20 percent come from a single facility, the Mountain Pass Mine in California.

To address this, Jha, Sudasinghe, and a team at Los Alamos are exploring an innovative approach: using engineered proteins to selectively bind and separate REEs from low-grade ores and waste streams.

“The idea was to create highly specific proteins that can bind REEs even at trace levels,” Jha says. “That means parts per million—or billion.”

Proteins are made of amino acids, and groups of these form peptides with distinct properties. In 2018, a protein called lanmodulin was found to have a natural affinity for lanthanides. The team is now engineering lanmodulin to fine-tune its specificity for individual REEs.

Using computational design, the researchers generate millions of peptide variants. But the real challenge is testing them. “Screening is the bottleneck,” Jha says. “We’re developing high-throughput methods using chimeric proteins—fusions of engineered peptides with fluorescent proteins. If an REE binds, the protein lights up, giving us quick feedback on affinity.” The goal is to ensure each peptide binds to only one REE, creating individual output streams.

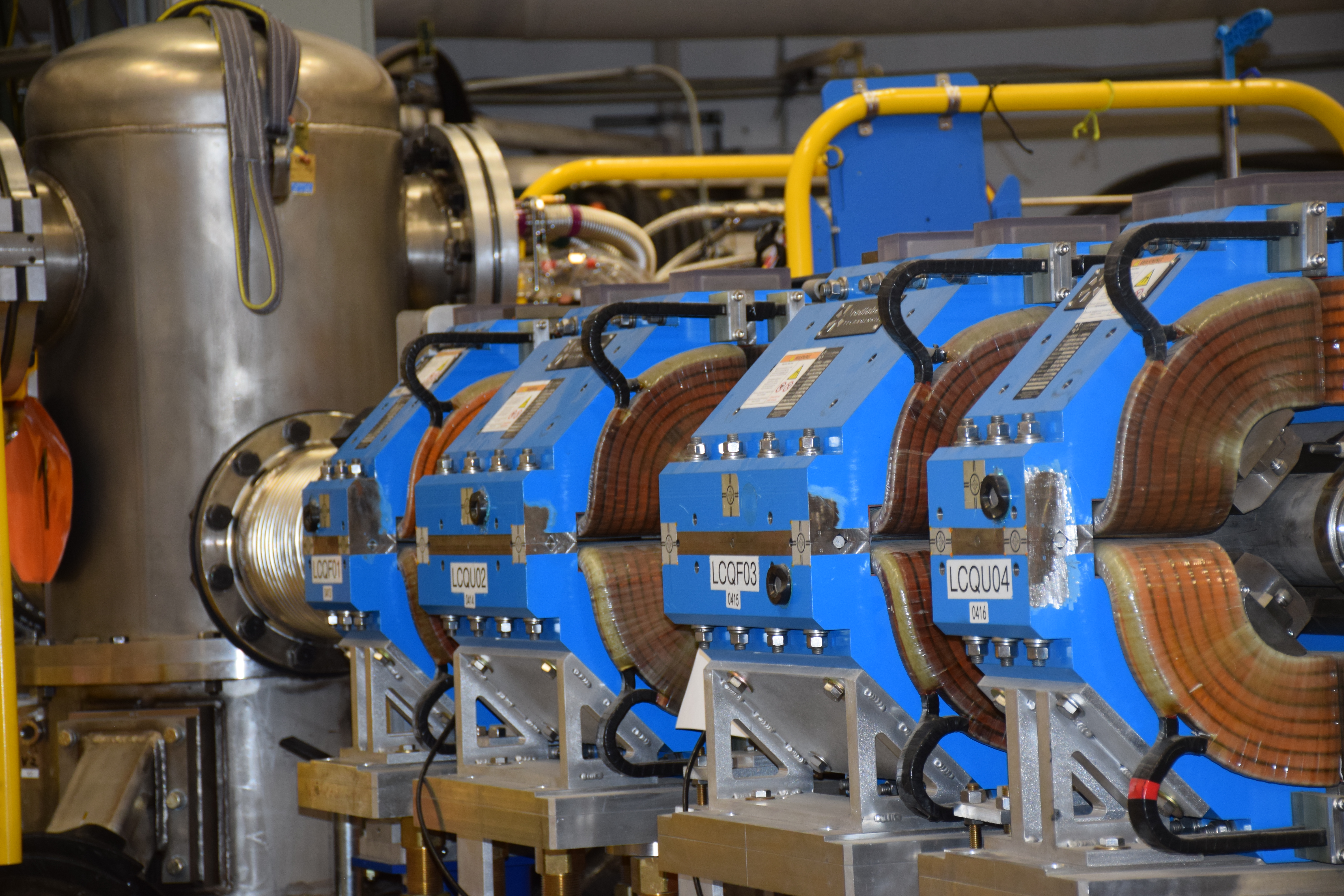

Now in year two of a three-year project, the team plans to build a lab-scale prototype: a series of columns, each packed with peptides targeting specific REEs. As feedstock passes through the columns, different REEs will be captured and later eluted (removed) using a pH shift.

“We want to test real sources by the end of year three,” Sudasinghe says. “This could open up recovery from electronic waste and other untapped sources.”

If successful, the technology could reduce toxic waste, enhance U.S. supply chains, and create a sustainable future for critical materials.

“It’s incredibly important,” Jha says, “and incredibly timely.” ★