Good vibrations

Los Alamos innovation delivers low-cost, cyber-resilient monitoring for industrial infrastructure.

- Ian Laird, Communications specialist

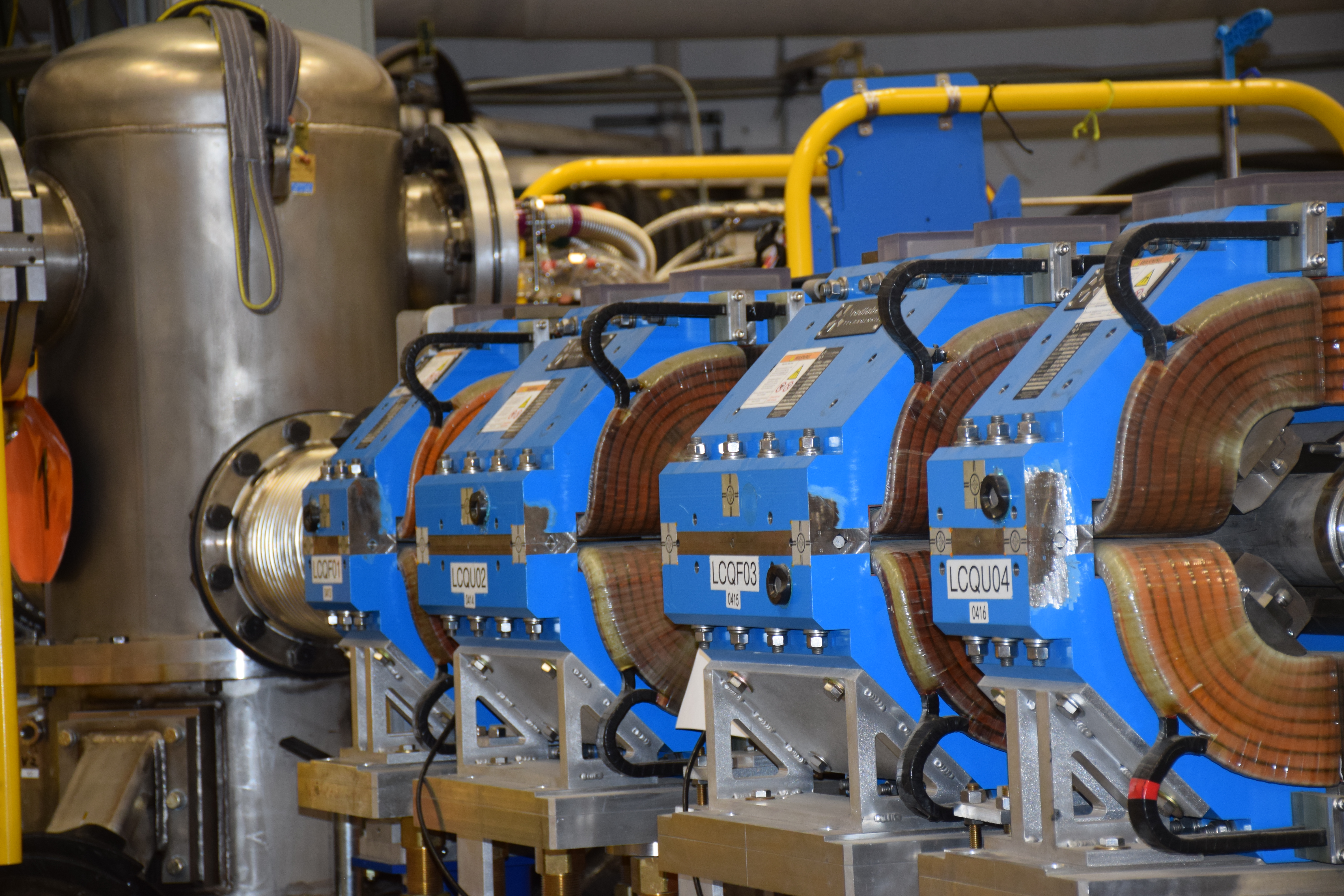

From drinking water to data center cooling, the movement of fluids depends on workhorse machines like pumps, compressors, and fans. These devices account for roughly one-third of global electricity consumption and form the backbone of countless systems. Ensuring their efficient and safe operation is crucial—but current monitoring methods have limitations.

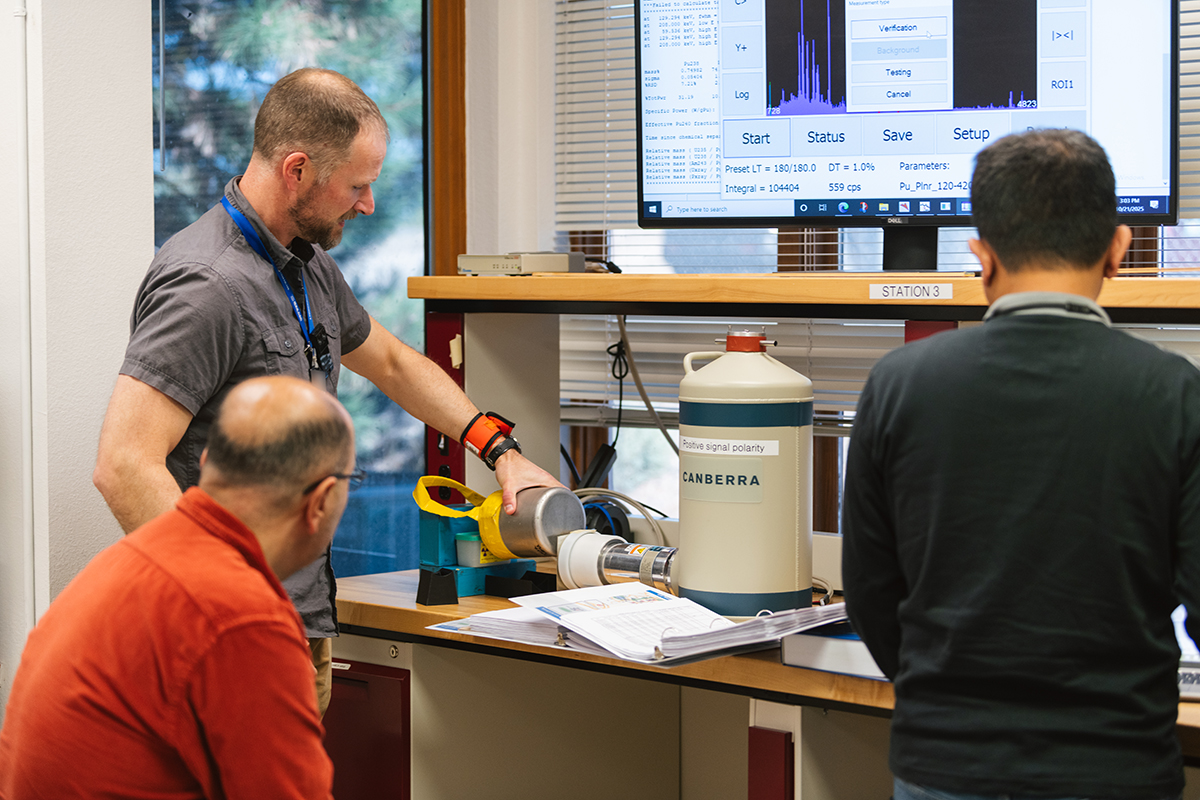

A team at Los Alamos National Laboratory believes they’ve developed a breakthrough alternative. Their technology, called VISION—short for Vibration Intelligence Systems for Industrial Operations and Networks—offers an affordable, flexible, and highly accurate way to track machine performance in real time.

“VISION enables a holistic view of an entire plant to track total performance,” says Neil Loychik, the engineer behind the technology. “It’s designed to overcome the limitations of traditional flow sensing by being low-cost and independent of any control system.”

Unlike conventional monitoring tools that can rely on direct flow measurements or integration with facility control systems, VISION taps into the mechanical feedback naturally generated by machines—specifically, their vibrations. Installed directly on infrastructure, the sensor captures vibration patterns that reveal how well a machine is running.

“It’s akin to knowing how fast a car or train is moving just by the vibrations in the tracks or road,” Loychik explains.

With machine-specific training, VISION learns the vibration signature of optimal performance. If a pump or fan deviates from that pattern, the system flags it—allowing for proactive maintenance or adjustments before problems escalate.

The financial case is compelling: according to Loychik, poor machine performance can rack up an average of $7,500 annually per unit in energy losses, maintenance costs, and downtime.

But the technology offers more than just efficiency. VISION also provides a unique cybersecurity advantage. In a digital attack, hackers may alter both a machine’s behavior and its reported metrics to conceal malicious activity. Because VISION operates independently of networked control systems and generates data from raw physical feedback, it can detect inconsistencies that spoofed software might miss.

“It’s a passive, independent check on performance,” Loychik says. “That makes it much harder to fool.”

Although VISION is not yet commercially deployed, the team has attracted interest from companies across various industries. Its low cost and wide applicability could make it an attractive upgrade to traditional monitoring systems, particularly in facilities aiming to improve reliability, reduce operational risk, and increase cyber resilience. ★