Fine-tuning flight testing

Los Alamos scientists send innovative technology soaring.

- Jill Gibson, Communications specialist

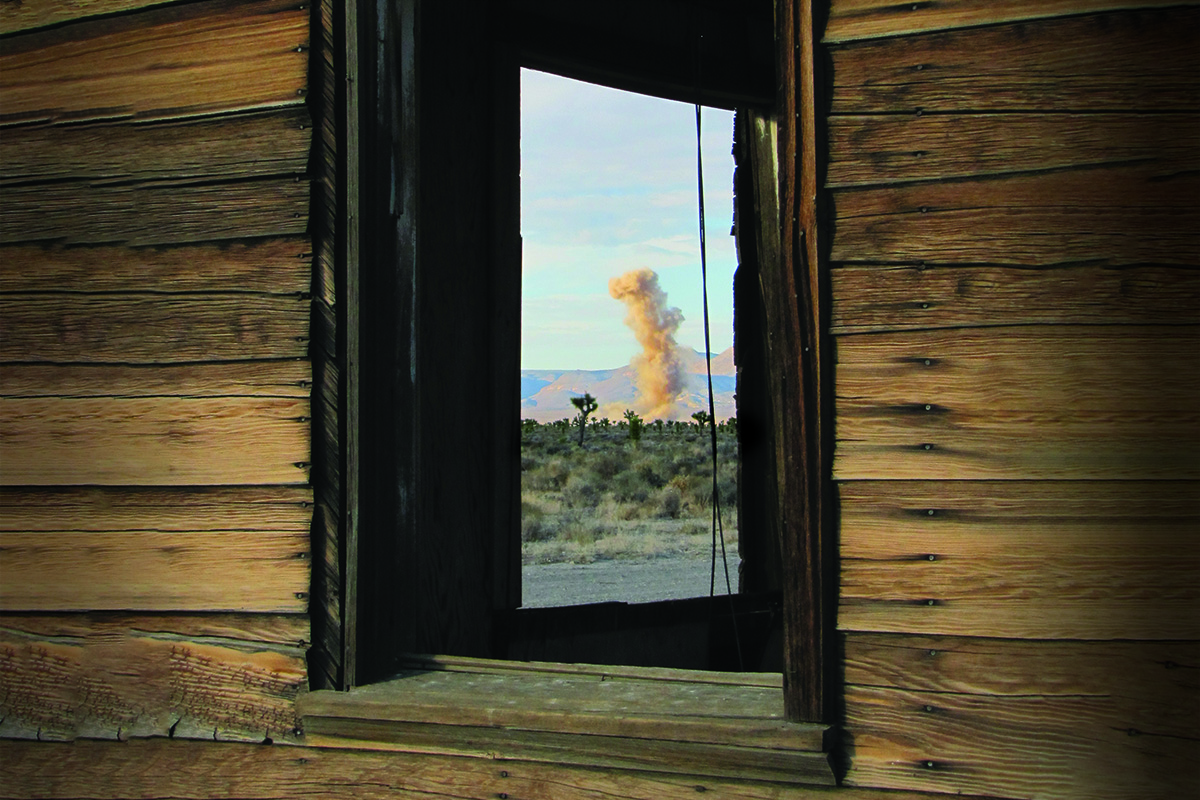

Los Alamos National Laboratory is celebrating advances in flight-testing capabilities following a rocket launch on June 13, 2025. The test launch, part of the Lab’s Stockpile Responsiveness Program (SRP), took place at White Sands Missile Range in partnership with commercial launch provider Up Aerospace Inc.

“This test required a hugely collaborative effort,” says Jordan Shoemaker, SRP deputy program manager and payload development lead for the launch. “It represents a leap forward in our capability to test new things at low cost and high cadence.”

This test marked several firsts for the Laboratory, which has successfully launched innovative payloads on commercial rockets since 2021. Suborbital flight tests allow scientists to determine how weapons technology and components perform in situations relevant to those seen in an intercontinental ballistic missile launch. For this particular launch, scientists deployed a payload of newly developed weapons technology and experimental components.

“This was also the first test of a new thermal protection material, a new integrated telemetry system, and a new additively manufactured titanium flight vehicle built by the Kansas City National Security Campus’ New Mexico Operations site,” Shoemaker says. (A flight vehicle is the cone on the end of the rocket that holds the payload.)

Cooperative weather conditions contributed to an on-time launch, and multiple data collection teams at different locations optimized data return, according to flight lead Justin McGlown, deputy senior project leader for the Lab’s Agile Space program. He notes that the onboard telemetry systems successfully transmitted data during the flight. Following the flight, the payload as well as the data recording systems (similar to an airplane’s black box) were recovered, and analysis of the results began.

“The data we receive is invaluable in allowing us to assess performance and make modifications to improve it,” McGlown says, adding that what sets the SRP apart is speed and affordability. “This program requires that we work quickly and keep down costs. Historically, launching a payload into space took years—sometimes decades—and hundreds of millions of dollars. This test integrated a new payload into a new vehicle, on a new rocket, including range costs, in just three years start-to-finish, at a significantly lower cost.”

Steve Judd, SRP program manager, says several more launches are on the schedule. “We spent several years building this capability, and now we are accelerating the cadence and using this capability to test the art of the possible for the future deterrent.” ★