Built to blast

Los Alamos engineers put explosives to the test.

- Jill Gibson, Communications specialist

Preparing for a high-explosives experiment at Los Alamos National Laboratory always sparks excitement, but the anticipation grows if the outcome is uncertain. “We don’t know exactly what’s going to happen,” says Matt Holmes, a team leader in the Explosive Applications and Special Projects group at the Laboratory. “This is exciting. It should be an interesting test.”

The test will occur at a firing site tucked away in a remote area of the Lab framed by massive cliffs of pockmarked pinkish-tan rock known as Bandelier tuff. Getting to the site requires driving down a dirt road past junipers and tumbleweeds. Ponderosa pines tower above.

“This is very much a science test,” Holmes says from the driver’s seat. “Often, when we test, we either know what’s going to happen or at least we think we know what’s going to happen. But not this time. We’re making predictions, but we don’t know.”

Holmes parks his Pathfinder at the site, though he will have to move it before the test to avoid possible damage from fragments and fire. The area hums with activity as engineers and technicians prepare.

A flight of metal stairs leads to a sandy, flat area located above a concrete bunker. The team will retreat to that bunker before the explosion occurs.

At the center of the flat area are 10 enormous concrete-and-rebar blocks arranged around the experiment—a stainless steel container holding an explosive charge. The blocks are topped with a solid steel panel covered in sandbags to form a shelter, called a blockhouse. This structure, which has two openings through which people can pass, was built to contain fragments from the explosion and prevent hot metal from flying into the nearby hills.

Holmes explains that the goal of the test is learn more about explosive safety so that explosives will never detonate accidentally. “It’s about knowing where the threshold is for dangerous accidents. We need to know at what point do we cross into an unsafe situation, and what makes it unsafe,” he says. “All of our tests explore these worst-case scenarios examining different variables. We have extremely high standards for safety.”

One of the variables the engineers are examining is the strength of the explosion. “What we think might happen here,” Holmes says, “is that upon detonation, the steel case will just pop apart, crack in pieces, and not do very much. My hypothesis is that it won’t explode with a great deal of force.”

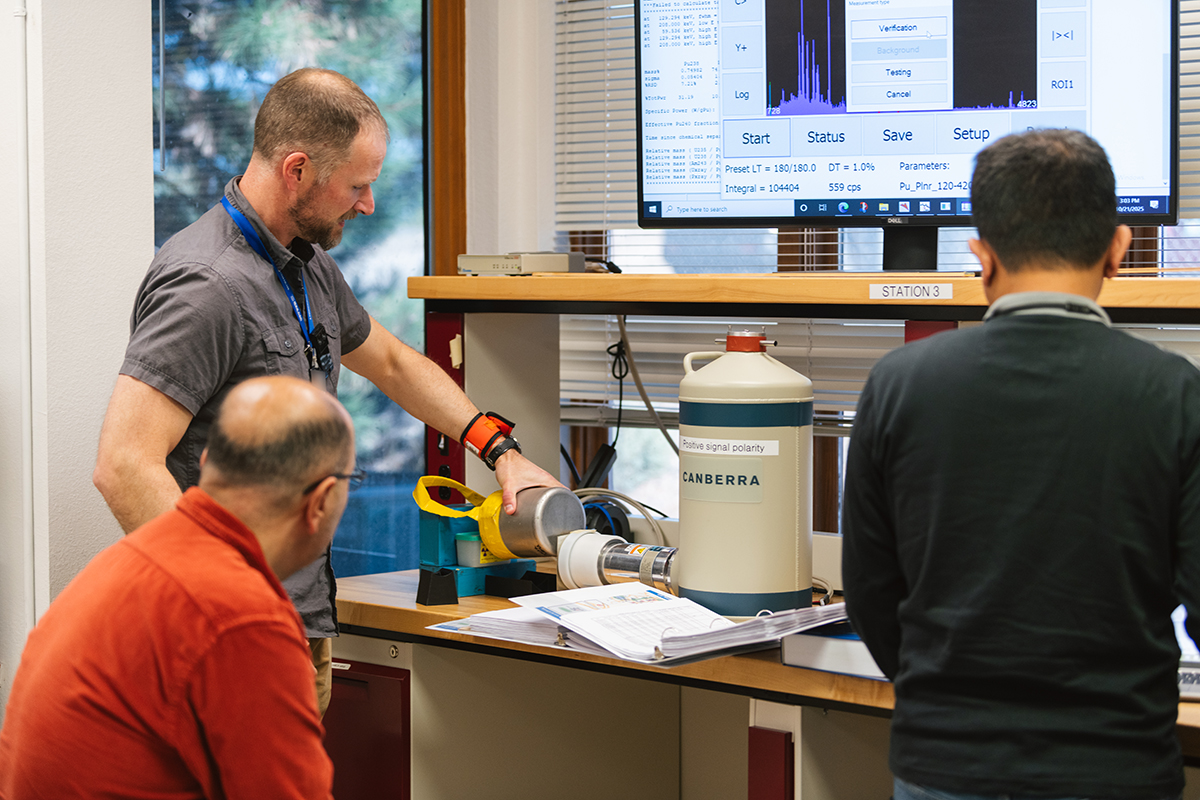

Holmes’ colleague Michael Erickson designed the experiment. Now Erickson works with technician Taylor Kress and engineer Thomas Macomber to set up a system of photonic doppler velocimetry (PDV) probes that will use lasers to measure the dynamics of the explosion.

While Macomber connects and positions probes, Holmes adjusts a system of mirrors that will allow the high-speed cameras peeking out from portholes built into the bunker to observe the blast without being destroyed by it. Extremely bright LED lights will help illuminate the explosion so the cameras can record the shot at more than 300,000 frames a second.

In addition to the high-speed cameras, less sophisticated surveillance cameras are in place to give the team an external view of the test from inside the bunker and allow them to monitor the area for smoke and fire following the blast. Getting ready has taken all afternoon, and soon, the sun will set.

As the final preparations begin, the surveillance cameras display video of the blockhouse, now vacated. All the team members are off the firing site and safely ensconced in the bunker below. They bustle around checking diagnostics and testing systems, all while discussing the possible outcome of the test.

Finally, with everything in place, the countdown begins.

“Firing in three, two, one…”

Even with hearing protection, the blast is ear-splitting. The bunker shudders from the explosion above, and the screens displaying the viewpoint of the surveillance cameras show only smoke.

Inside the bunker, people exchange shocked glances.

“Damn,” Holmes says. “That’s not going to be easy to clean up.”

Moments later, after using the surveillance cameras to scan the site and nearby area, firing leader Dennis Jaramillo gives the okay to leave the bunker. Hurrying up the metal stairs to the firing site, the team members see the aftermath of the blast. The blockhouse is in shambles—the concrete blocks blown far from their original positions, some cracked, exposing twisted rebar.

The heavy steel roof of the blockhouse appears to have been thrust upward and flipped over. Scraps of nylon are all that remain of the sandbags. Fragments of metal and concrete, still warm from the blast, are strewn across the firing site. An iron girder lies on its side, thrown by the power of the explosion.

The engineers swarm around the site, picking up twisted hunks of steel and pointing out holes where shrapnel pierced the bunkhouse roof.

“That’s a crater,” Erickson exclaims, looking at the shallow hole where the explosive charge, tightly bolted into a thick steel shell, once stood. “I did not expect it to look like this.”

“It exploded very violently,” Holmes says. “Now we have the diagnostics to study what exactly happened.”

Team members walk around the firing site, speaking in hushed tones and analyzing the remains of their experiment. “There’s a week’s worth of work right there,” Macomber says. “Just blew that up.”

“That’s why we do this,” Holmes explains. “This is the way we get the answers we need to ensure our explosives are safe.”

The sun is sinking below the rocky cliffs as one of the younger engineers looks around the rubble-filled firing site and asks Holmes, “When can we do the next test?”

“We’ll start cleaning up tomorrow,” Holmes replies with a smile. “Then we set up for the next test.” ★