A smarter, faster inspection

A new tool enhances speed and accuracy in national security manufacturing.

- Audra Short, Communications specialist

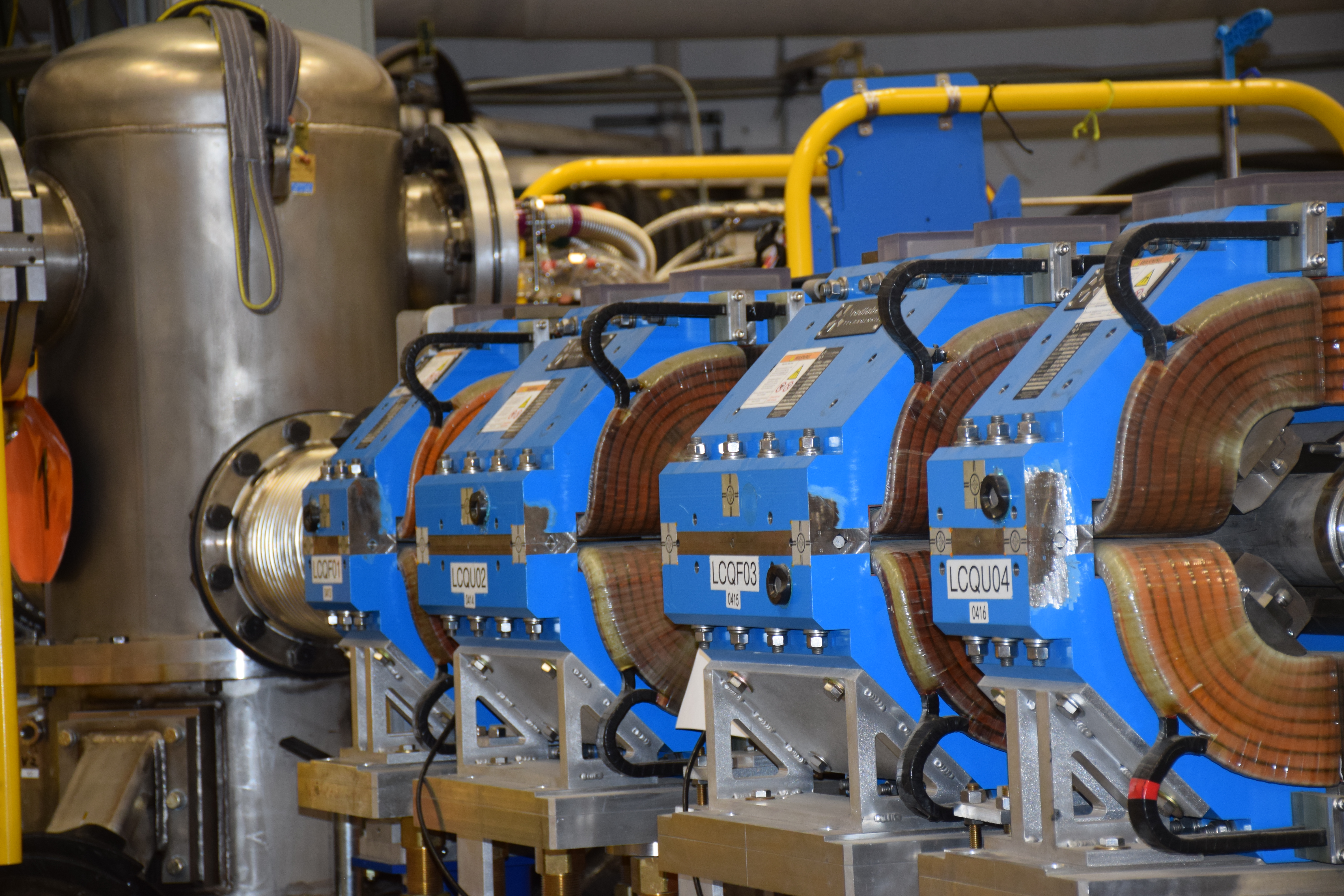

From plutonium pits and detonators to space instruments and beyond, Los Alamos National Laboratory manufactures critical parts in support of its national security mission.

Because precision is paramount—slight deviations can have significant consequences for safety, functionality, and cost—every component is inspected to ensure it meets exact engineering specifications.

However, traditional inspection methods have limitations. Coordinate measuring machines (CMMs), for example, offer excellent accuracy but are slow—capturing just tens of measurements per minute. For an item requiring 18,000 measurements, a CMM can take up to 10 hours.

Faster alternatives, like optical scanners, can complete the same task in 30 minutes, but lack the necessary precision.

To bridge the gap between speed and accuracy, a team of Los Alamos engineers developed the Intelligent, Rapid, & Optimized Dimensional Inspection (IRODI). This patent-pending solution merges existing dimensional inspection hardware with Maestro, an innovative statistical inspection optimization software.

Maestro compares initial inspection data against the original computer-aided design (CAD) specifications. Instead of scanning the entire part indiscriminately, it focuses on high-risk areas, autonomously refining measurements until the desired confidence level is achieved.

“Maestro is designed to deliver an unmatched competitive advantage in the inspection industry,” explains software designer Sarah Brown. “Maestro intelligently inspects points, reduces the number of required measurements, and predicts the actual surface contour with a high level of confidence and accuracy.”

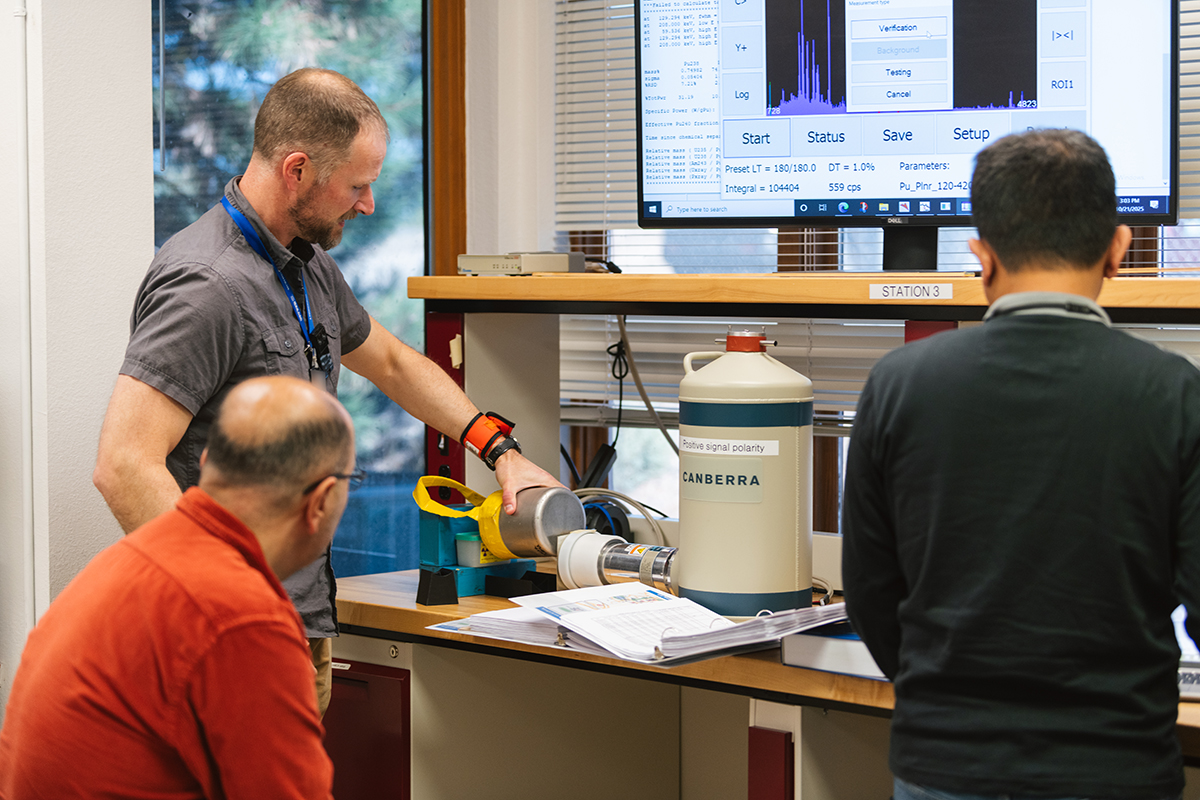

IRODI offers faster inspections (what once took 10 hours now takes just 1), higher precision (detecting small defects that traditional CMMs might miss), and smarter targeting (reducing unnecessary measurements while ensuring accuracy).

IRODI isn’t just for finished products—it’s also useful during manufacturing. By inspecting parts in-process, manufacturers can detect and fix defects in real time, reducing waste, cutting costs, and improving efficiency.

Even better, IRODI integrates seamlessly with existing inspection tools, eliminating the need for costly hardware upgrades. It’s scalable, supporting both small- and large-scale manufacturing across additive and subtractive processes.

IRODI’s potential extends well beyond the Laboratory’s national security mission. Industries such as aerospace, defense, automotive, healthcare, and more stand to benefit.

“Manufacturing impacts every aspect of our lives—transportation, food production, communication, energy, entertainment, medical devices—the list goes on,” says John Bernardin, who leads the team behind IRODI. “While IRODI is crucial to Los Alamos, its influence will be felt far beyond our Lab.”

With unmatched speed, accuracy, and efficiency, IRODI is set to redefine how critical components are inspected—ensuring safer, stronger, and more reliable manufacturing for years to come. ★

Article by Audra Short, communications specialist