Accelerator Armor

A new approach to reducing downtime at the Lab’s largest accelerator

- Eleanor Hutterer, Editor

Download a print-friendly version of this article.

The linear accelerator at the Los Alamos Neutron Science Center (LANSCE) is the largest particle accelerator at the Lab, and for 52 years it has enabled an ever-increasing array of research in fields like nuclear physics and materials science. A beam of 800 mega-electron-volt protons shoots down a half-mile-long underground corridor, feeding protons into five specialty facilities: the Isotope Production Facility, the Proton Radiography Facility, the Ultracold Neutron Facility, the Weapons Neutron Research Center, and the Lujan Neutron Scattering Center. Each year, LANSCE receives more than 700 user visits by scientists from across the Lab and around the world.

The best way to maximize beamtime is to replace ion sources less often, and the way to do that is to help them live longer.

But in a typical year, every 28 days, beam-dependent work stops for 2 to 3 days while technicians replace a vital part of the proton beam: the negative ion source. The disruption not only costs 24–36 days of beamtime per year, but it also requires scientists to schedule their work around these outages, which further slows things down. Laboratory physicist Janardan Upadhyay is working on a way to reduce the number of days per year that the beamline goes offline.

“Over the past 30 years, there hasn’t been any change to this process to replace the ion source and get it operational faster,” says Upadhyay. “A recent 6-month run involved 6 replacements and about 15 days of downtime.”

Replacement takes 2 to 3 days because the new ion source has to be put under vacuum, which takes at least 12 hours, and it has to be brought up to operating current gradually, which takes another 18 hours. Because these timelines are fixed, Upadhyay realized that the best way to maximize beamtime is to replace ion sources less often, and the way to do that is to help them live longer.

The negative ion source is a stainless steel confinement chamber, about the size and shape of a one-gallon paint can, that sits at the very beginning of the LANSCE beamline. Its job is to produce the H- ions for the proton beam, a high-power process that is hard on the materials involved. (The LANSCE beam is made up of both H+ and H- ions, but the negative ion source only contributes H-.) Within the confinement chamber is a small tungsten filament, and it’s this filament that fails.

Production of the proton beam starts with the tungsten filament: it gets heated to 1727° C, which causes it to spew out high-energy electrons in a process called thermionic emission. These electrons interact with hydrogen gas that is supplied to the confinement chamber, resulting in a hot plasma of hydrogen ions that fills the chamber. A cesium charge converter within the chamber converts H+ ions to H-, then an electric potential applied to the plasma extracts the H- ions out of the negative ion source, whereupon they are accelerated down the beamline.

But cesium, while necessary for charge conversion, is also corrosive. And the extreme temperature causes ions to rocket around the chamber, battering the filament in an effect called back-bombardment. Continual back-bombardment combined with the high temperature and corrosive side effects of the cesium all contribute to filament deterioration. The higher the electrical current, the more quickly damage accrues, so to ensure a filament lasts the full 28 days, the ion source current is routinely suppressed, limiting the pace of decline but also limiting the beam current available for users’ experiments.

The extreme temperature causes ions to rocket around the chamber, battering the filament.

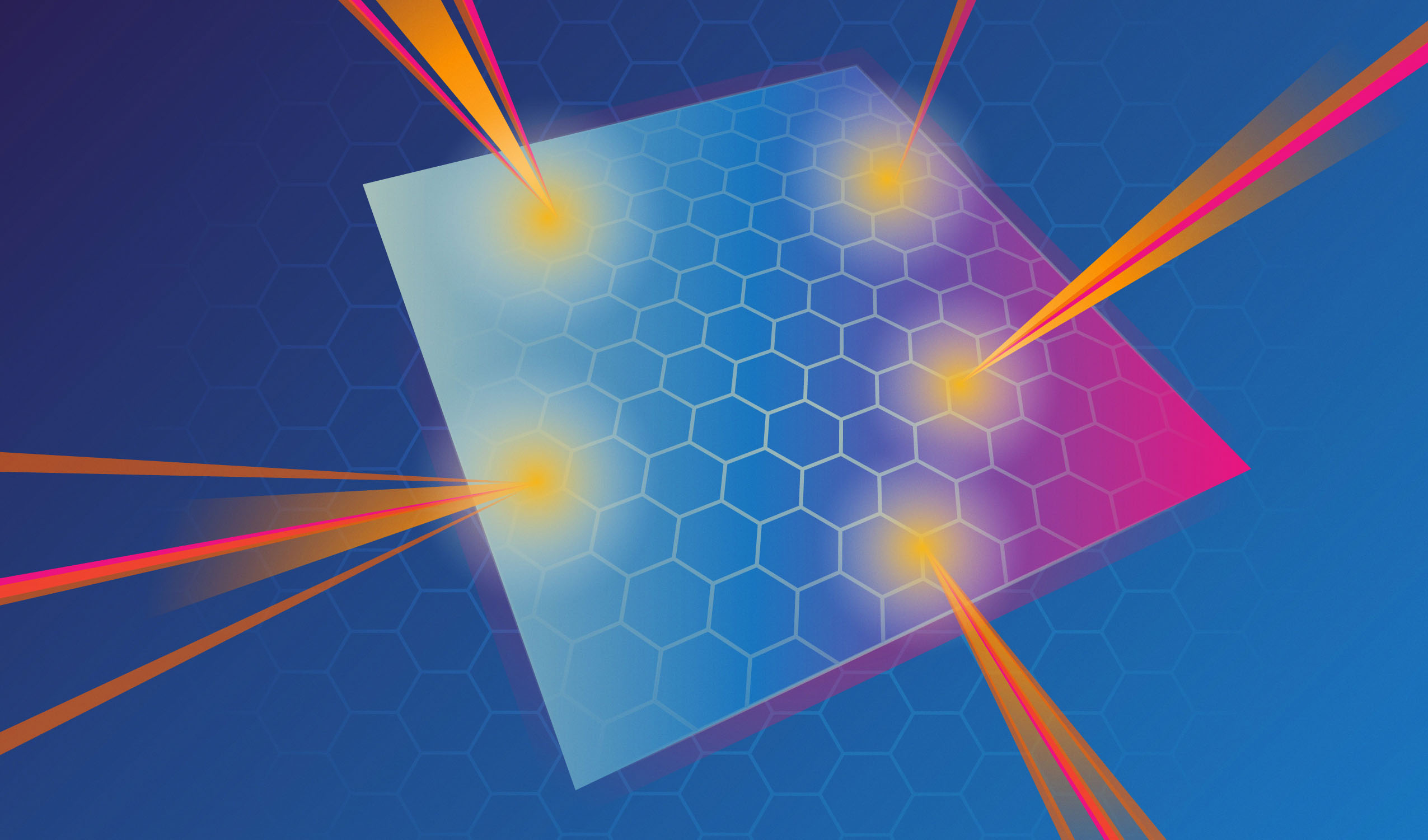

Upadhyay thought that graphene, a super-strong and versatile one-atom-thick sheet of pure carbon, wrapped around the filaments, might work to shield them from back-bombardment. So, he reached out to Lab materials scientist Hisato Yamaguchi, a graphene expert who previously helped develop a graphene-based protective coating called Atomic Armor, for certain highly sensitive materials. Together, they have been testing different ways that Atomic Armor might extend the lives of ion source filaments.

Three properties make graphene a good choice. First, its packed atomic structure does not allow any gases, not even hydrogen gas, to get through. Second, it is only one or two atoms thick, meaning that electrons being emitted from the filament can pass easily through—any thicker and the electrons could be blocked. Finally, graphene is chemically and mechanically super stable, as any good shield should be.

Upadhyay, Yamaguchi, and a team of collaborators first tried coating the filament directly with graphene, but found that when heated to operating temperatures, the graphene coating came off. The team is presently looking at adjustments to the heating speed that could prevent the graphene from delaminating from the filament. But next, instead of coating the filament itself, they tried coating a stainless steel mesh cage that could surround the filament, like a terrarium for a snake (the filament is vaguely snake shaped). This time, when heated to operating temperatures, not only did the graphene survive, but it functioned as desired, letting high-energy electrons pass through and blocking back-bombardment. Now that they know a graphene-coated shield can work, the scientists are doing experiments to delineate important metrics like optimal filament-shield distance and maximum effective graphene thickness.

“Tungsten isn’t the absolute best emitter, but it stands up to back-bombardment. If we can block back-bombardment with graphene, then we can explore better emitting materials.”

Another approach that Upadhyay and the team are pursuing is a coaxial jacket made of graphene-coated steel mesh. In this case, instead of an enclosure, it’s more of an encasement, like a snake wearing a sweater. In the coaxial-jacket design, the filament and mesh will each function as electrodes and will be separated by a dielectric material at either end to keep them isolated. This will allow for the application of a voltage between the electrodes which, when varied, would enable finer control of current. It would also eliminate the need to suppress the current, thereby relieving LANSCE users of that restriction.

“We also might be able to use better materials for the filaments,” says Upadhyay. “Tungsten isn’t the absolute best emitter, but it stands up to back-bombardment better than other materials. If we can block back-bombardment with graphene, then we can explore filaments made from better emitting materials.”

The LANSCE proton beam is essential to science at the Laboratory. And Upadhyay is confident that Atomic Armor can help modernize it, whether it’s with a coating, a cage, or a casing. Extending the lives of ion source filaments will help keep the electrons flowing, the protons beaming, and science steadily marching on.

People Also Ask

- What is graphene? Graphene is a material made from a single layer of carbon atoms, arranged in a planar hexagonal grid. It is the thinnest two-dimensional material in the world and known for its tensile strength, optical transparency, electrical conductivity. First proposed theoretically in 1947, it wasn’t physically isolated until 2004, for which British physicists Andre Geim and Konstantin Novoselov received the 2010 Nobel Prize in physics.

- How is graphene made? There are different ways to isolate graphene. The first isolation of graphene was achieved by putting sticky tape on a piece of graphite then pulling the tape off, along with a single layer of carbon atoms. Additional methods for isolating graphene layers from graphite include using chemicals to create graphene flakes, using electricity to force graphene layers apart, and using soundwaves to vibrate graphene layers apart. Graphene can also be assembled one carbon atom at a time. When a hydrocarbon gas, like methane, is heated to about 1000°C in the presence of a metal substrate, the gas molecules decompose and their carbon atoms naturally adhere to the metal substrate and assemble into a layer of graphene.