Dressing up in tuxedos and evening gowns has become commonplace for the Low Temperature Detectors team (NEN-1), which has received three consecutive innovation awards since 2022 in competitions sponsored by R&D World Magazine.

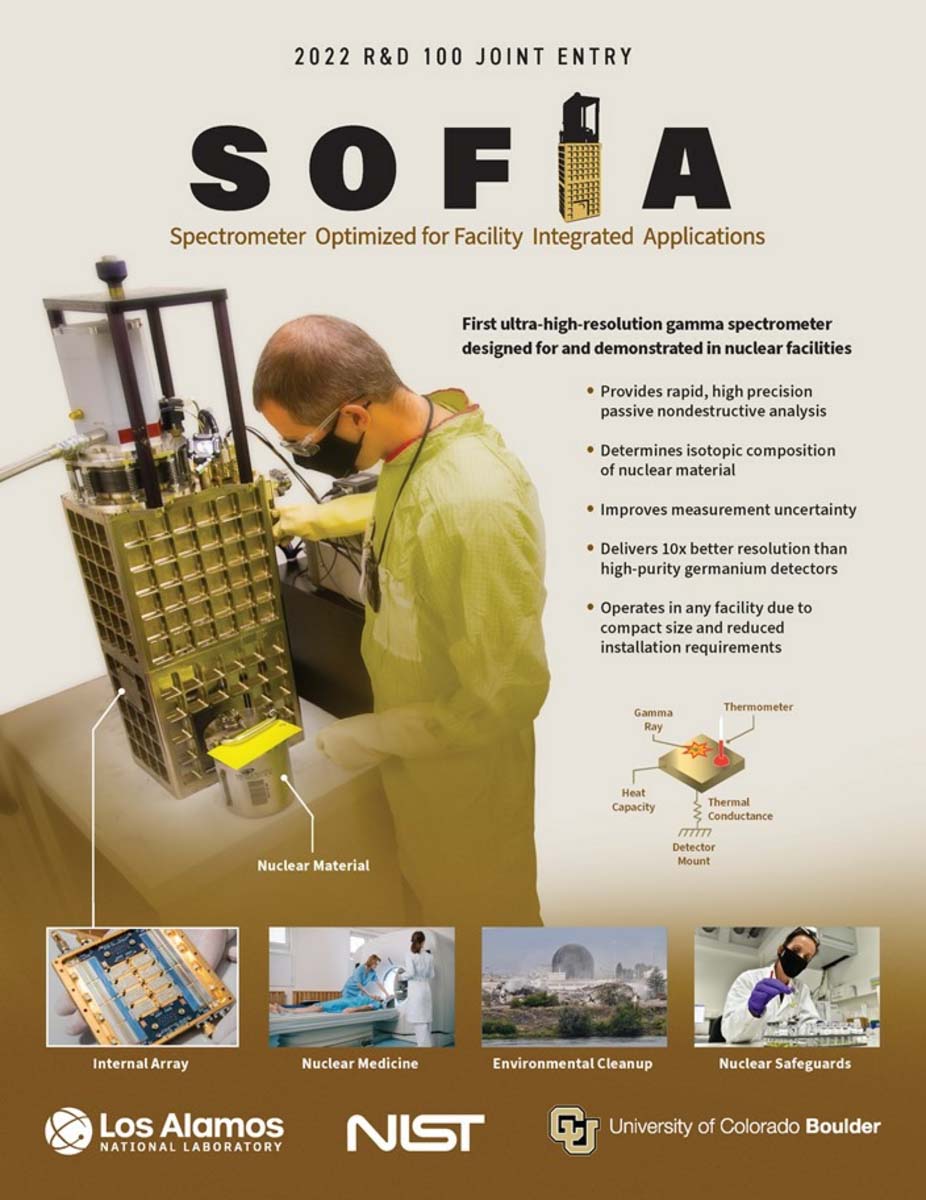

The invention that's taking off now was their first win: the Spectrometer Optimized for Facility Integrated Applications (SOFIA). Specifically, SOFIA collects data crucial for tracking and safeguarding nuclear material at reactors and other facilities. The technology offers high-quality information about the proportions of radionuclides (unstable, radiation-releasing forms of a chemical element) in nuclear materials without the need for sampling or destructive analysis.

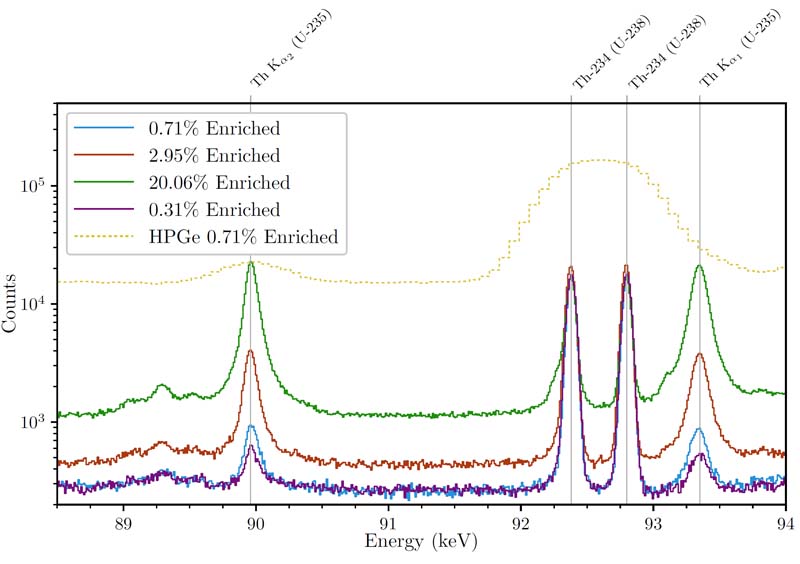

Here's how SOFIA works: Place a nuclear material container in front of the instrument (located in a lab) and wait. Collect gamma rays emitted from the natural radioactive decay of the material. The resulting energy spectrum is collected over a few hours, and then you can determine the isotopic ratios, such as uranium enrichment. SOFIA offers such precision and accuracy that nuclear facilities and inspectors need to comply with regulations and international treaties at a dramatically reduced cost relative to conventional laboratory analyses.

The SOFIA gamma spectrometer is expected to be deployed at the Lab's Plutonium Facility soon for nuclear material accountability. And similar instruments built by the team are already operating at Idaho and Pacific Northwest national laboratories while its data analysis capability is being fine-tuned.

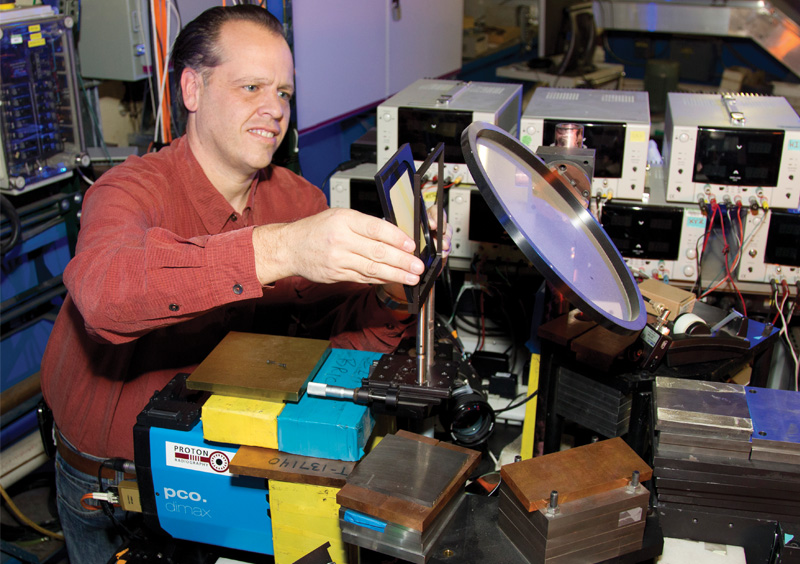

"It's an exciting time right now because we built these tools. They're now out there doing measurements," says outgoing team leader Mark Croce, who has taken a temporary assignment with NNSA's Office of International Nuclear Safeguards. "And it seems like with almost every spectrum we collect, there's some new, interesting information. Maybe peaks that people have never observed before or have never been able to use for analysis."

Shrinking SOFIA

The Low Temperature Detectors team is rooted in a collaboration that began in 2005 between the Laboratory and the National Institute of Standards and Technology. That collaboration led to SOFIA's creation — an effort between Lab scientists working with NIST and researchers from the University of Colorado Boulder.

NEN-1 scientists spent years ratcheting up the detector's performance to an admirable level, but then the instrument was too expensive and difficult to use. Early low-temperature cryogenic refrigerators, which were needed to maintain the detector operating temperature (below 0.1 Kelvin), took up an entire corner of a room with heavy electrical and cooling needs.

"We looked at the system and thought, 'How can we shrink this down to be more portable, even if we make it worse?' Meaning, if we downsize the cryogenic components so they are smaller, lighter and have less stringent facilities requirements — and in the process sacrifice performance — would we still have a product that is capable?" recalls acting team leader Matt Carpenter.

It turns out the answer was yes, and after a rework, wider adoption of this class of detector is now possible. The latest SOFIA detector is much smaller and requires less power. It's also more user friendly thanks to readout electronics and analysis software.

"They have taken this technology from a very low technology-readiness level to a highly developed state with many installations outside of the LANL lab environment," says scientist Mike Browne. "This is extraordinarily rare and speaks to the quality of the technology, commitment of the team and their technical integrity."

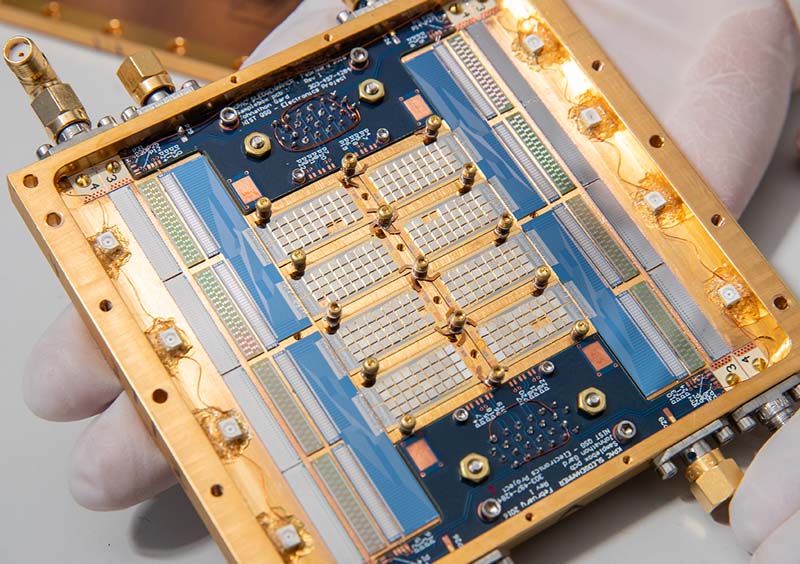

SOFIA's core technology is a low-temperature superconducting sensor, which has traditionally been used for physics research.

"It's essentially a better camera for seeing the radiation from nuclear materials. There's this exotic class of sensors that gives us extremely high-energy resolution, like a camera that makes much sharper images than anything commercially available," Croce says. "You can nondestructively account for the composition of material throughout the nuclear fuel cycle and verify that with a higher level of precision."

Extremely low temperatures are necessary for the detector's superconducting sensors to function with such high sensitivity, and SOFIA's sensors are located inside a cryostat to keep them cold. Radiation from the sample outside the cryostat reaches the sensors through windows in the walls of the cryostat.

As the team adapted commercial sub-Kelvin cryostats to increasingly diverse applications, they ran into problems with reliability and performance. Each team member had to learn how to troubleshoot and modify cryostats to get things working. Sometimes, they had to turn to vendors for help.

"I think our team's special contribution was that we put a lot of existing pieces together into this new package,” Croce says. “We took the smallest commercially available cryostat that can get to these temperatures, and we retrofitted it with a low-power pulse tube cryocooler. That dramatically reduced the power and facility requirements.

"The transformative moment was when our collaborators developed this idea of using software-defined radio on FPGA (Field-Programmable Gate Array) platforms that you can just buy.”

SOFIA now has bragging rights as the first application of this high-bandwidth, very capable readout to a large sensor array.

The bedrock of SOFIA's success goes back to the team's longstanding bonds with NIST. The team worked closely with NIST to develop the detector technology, but it relied solely on NIST to fabricate the detector devices and customize the readout electronics.

"Our close, collaborative relationship with them is critical," Carpenter says. "Rather than a customer/vendor relationship, it is more like an academic collaboration with regular meetings and discussion. Without that, we would not be where we are today, nor would we be able to troubleshoot our problems effectively."

From physics experiment to practical instrument

SOFIA is the first ultra-high-resolution gamma spectrometer based on low-temperature microcalorimeter technology. Designed for nuclear facilities, the instrument improves nuclear safeguards and security by reducing costly sampling and time-consuming destructive analysis.

It could lead to fewer processing delays at the Lab's Plutonium Facility or better-quality radioisotope production, like for medical isotopes.

But the team was especially eager to share their breakthroughs with DOE's Office of Nuclear Energy, because faster, cheaper, better material accounting could help the rapidly growing field of advanced nuclear energy.

"We've been doing some very cool experiments with Oak Ridge National Laboratory to look at the feasibility of real-time material accounting in advanced nuclear reactors," Croce says. "You need to be able to quantify the uranium, plutonium and other content of the fuel, and look at the effect of very short-lived fission products. Making these measurements allows us to see some new information about the fuel content."

With future cryogenic advancements on the horizon, the team hopes to come up with a SOFIA 2 version that's even more portable.

Building a dream team

Officially formed in February 2023 within the Safeguards Science and Technology group, the Low Temperature Detectors team has a rich 20-year pedigree in the Lab's global security organization. The group adapts and develops technologies to measure and track nuclear material worldwide, and over the years a handful of pioneers have worked on advancing low-temperature detectors to help ensure the safe and secure use of nuclear power.

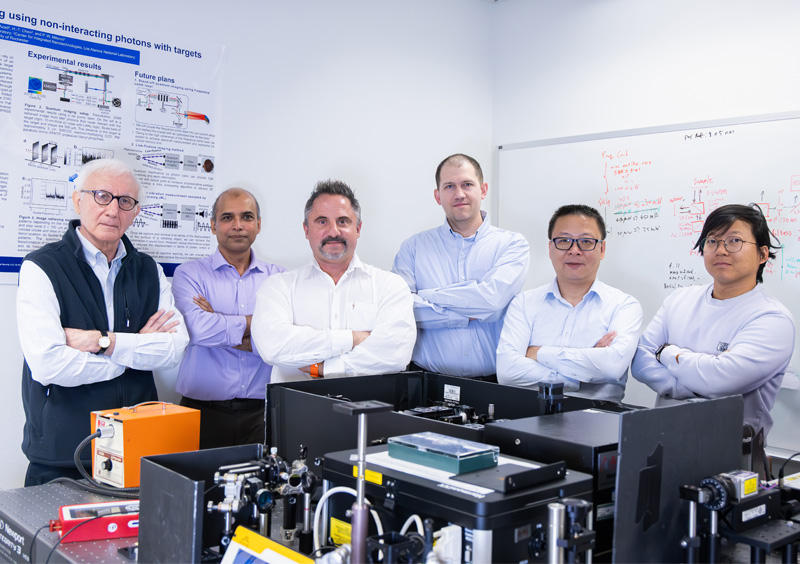

Twelve full-time members and multiple summer students make up the Low Temperature Detectors team.

"Our team has grown by focusing on a particular cutting-edge technology: sub-Kelvin superconducting detectors," Carpenter says. "Innovative thinking has been part of our team from the start due to our focus on adapting this complex and novel detector technology for more routine uses. LTDs are a whole subfield of detector physics and technology on their own, so our success has come from years of study and in-house learning to tackle the unique challenges these detectors pose."

To get problems in the right hands to solve them, the team recruited specialists in different areas such as cryogenic engineering, data science, software development and instrumentation.

"I joined the team as an outsider, coming from data science and machine learning into a team of hardware experts for these really crazy detectors," says Emily Stark. "While intimidating, I think the innovation and scientific discovery that our team is capable of is a direct product of bringing in people from different fields to work together."

Coaxing an idea from spark to execution might mean an idea that's informed from the computational side; for example, inspiring brainstorming from other areas.

"By the time we reach a solution, it's a unique amalgamation of physics, engineering and statistics," Stark says.

Togetherness is their style

If you hung out with this team for a week, here's what you would see:

- An atypically close-knit team with constant interaction and shared projects.

- Frequent team meetings to brainstorm so people are not sent off alone to work on solutions for too long.

- Offices adjacent to one another with a lab, a machine shop and an electronics shop just down the hall.

- Members who specialize in subfields (e.g., gamma spectroscopy, alpha spectroscopy, X-ray spectroscopy) but with plenty of "cross-pollination" and shared resources common to all areas.

- A team leader who doesn't trust his own ideas until they've been validated by other team members.