A promising method for alloying depleted uranium

Overcoming the challenges of metal alloying

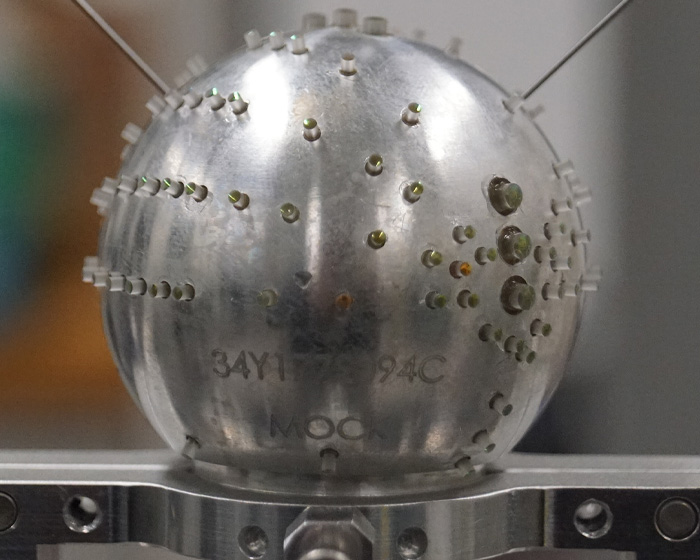

Metal alloying—or mixing elements to form a material with specific properties—is one of the challenging manufacturing science areas for which Sigma Division is known. Seth Imhoff and Kara Luitjohan (both Sigma Division) are part of a research team exploring a new way of alloying depleted uranium and niobium to meet a need described in the nation’s Stockpile Stewardship and Management Plan.

“While many technologies are currently being explored, the concept of direct alloying is one of the most material efficient options, if we can continue toward developing it into a robust and predictable process,” Imhoff said.

Can we do it?

The Sigma team was able to do it in part because they decided to take a chance and see if they could get it to work. This was a calculated risk, informed by a promising experiment at the Y-12 National Security Complex. “We were able to conduct many trials in a short period of time,” Luitjohan said.

What it took

The initial results of direct alloying depleted uranium and niobium were mediocre, but Sigma scientists were able to get to a more promising outlook by exploring the impact of key variables. “The ability to maintain that progress can be attributed to a great deal of fast turnaround work by multiple teams across the Sigma Division, including 8 of the 13 teams from Sigma,” Luitjohan said.

The happy customers

“This research is a major accomplishment, for not only Rob [Aikin], Seth, and Kara, but the entire complex. In just 18 days, we had our first part; this kind of turnaround is unheard of and should be celebrated,” said Depleted Uranium Modernization Program Manager Rita Campbell (Sigma Division). “Direct alloying has the potential to reduce risk through the reduction of processes, many of which are single points of failure.”

The Sigma direct alloy team received kudos from NNSA management, the Depleted Uranium Modernization federal program director, and the Office of Production Modernization (NA-19). “Many at NNSA headquarters are excited about the continued development of this process,” Campbell said. The goal is to ensure that direct alloying is a robust and predictable process, and experiments are ongoing.

Stockpile Stewardship and Management Plan

In 1992, the United States declared a moratorium on nuclear weapons tests. Weapons in storage are damaged over time by their own radioactivity and need replacement parts. The annual Stockpile Stewardship and Management Plan from NNSA to Congress outlines the work required to keep the nation’s stockpiled nuclear weapons in top condition without trying them out, and to support new weapon development. Depleted uranium modernization, one priority in the plan, aims to overcome supply challenges and restore manufacturing capabilities for weapon components.

Depleted uranium

Uranium from which most of the fissile isotope uranium-235 has been removed. It is required for nuclear component production to maintain and modernize the stockpile through life extension, modification, and limited life component exchange programs.

Sigma

A division of the Lab and a facility. This division in the Physical Sciences Directorate develops materials and components using engineering and metallurgical science in support of national security. The Sigma Complex has a foundry and machines to advance manufacturing science.

NNSA’s nuclear security enterprise (or complex)

A network of eight research laboratories and nuclear weapons production facilities supporting the maintenance and modernization of the nation’s stockpiled nuclear weapons.