STE Highlights, August 2021

Awards and Recognition

Capability Enhancement

LANSCE neutron beam transport optimized via advanced collimation design techniques

Chemistry

C3Lab updates enhance custom gas mixture capability

Advances in catalytic hydrogenation with non-transition metals

Physics

‘Computer vision’ techniques track plasma flow features

Self-assembly monolayer boosts efficiency and lifetime of perovskite solar cells

Awards and Recognition

Gibbs awarded 2021 ASM Bronze Medal Award

Meghan Gibbs

Meghan Gibbs, an R&D engineer in the Nuclear Materials Science Group (MST-16), has been recognized with the 2021 ASM Bronze Medal Award, awarded by ASM International, the world’s largest materials science and engineering society. ASM International cited Gibbs for “excellence in process modelling, manufacturing science, and professional service impacting the U.S. steel industry and product qualification for the U.S. Nuclear Deterrent.”

The society’s highly competitive Bronze Medal — only two were awarded this year — recognizes ASM members who are in early-career positions for their significant contributions in the field of materials science and engineering through technical content and service to ASM and the materials science profession. On the Materials Properties team since joining the Lab in 2015, Gibbs studies plutonium casting, including process modeling, mold design, and process development in support of manufacturing and science programs. Gibbs is also interested in plutonium thermophysical properties and plutonium aging studies. She received her bachelor’s degree in 2008 and her master’s degree in 2011, both in metallurgical and materials engineering, from Colorado School of Mines. Prior to joining LANL, she worked as a control metallurgist for five years at an ArcelorMittal steel manufacturing facility.

Gibbs was nominated by ASM International’s Los Alamos chapter, where she has held several leadership positions since joining LANL. The chapter offers awards and scholarships to local high school and college students, takes part in science fairs, and has participated in STEM programs at the high school. Gibbs will receive the Bronze Medal at IMAT 2022, the International Materials Applications & Technologies Conference and Exhibition, the society’s annual meeting.

Klein featured by NNSA for cutting-edge work in AI for national security

Natalie Klein

Natalie Klein of Statistical Sciences (CCS-6) recently had her work featured in an NNSA article on a national collaboration to drive next-generation in artificial intelligence (AI) for nonproliferation. Her project, titled “One-Shot Target Detection Via Physics-Informed Training,” investigates one of the common challenges faced in AI for a specific domain of knowledge, which is a lack of usable data.

Klein and her team worked to train a deep neural network to reliably characterize materials on the ground, even in the absence of such comprehensive training images from hyperspectral data. To overcome this lack of data, the team generated its own synthetic data using the team’s domain-specific knowledge of physics and chemistry. Informed by this generated data, the network was then able to accurately detect materials, even when faced with new and authentic data containing novel materials and unseen environmental conditions.

Klein anticipates the model could be applied to quickly detect materials in new data without needing to account for environmental conditions that may influence the signatures. This type of airborne detection could be used to recognize nuclear materials in support of nonproliferation efforts.

Wenting Li awarded Best Paper for Machine Learning Innovation

Wenting Li

Wenting Li, a postdoctoral fellow in the Center for Nonlinear Studies and the Applied Mathematics and Plasma Physics (T-5) group, recently received a Best Paper award for Machine Learning (ML) Innovation at the Climate Change artificial intelligence (AI) workshop at the 2021 International Conference on Machine Learning (ICML).

She designs graph neural networks using physics to identify the location of power grid faults that may trigger wildfires. The highlight of this research is that it can work in realistic regimes where power networks are sparsely observed and data is partially labeled.

The link to the winning paper and video can be found at https://www.climatechange.ai/papers/icml2021/11.

Bioscience

Understanding glass transition temperature for biodegradable plastics

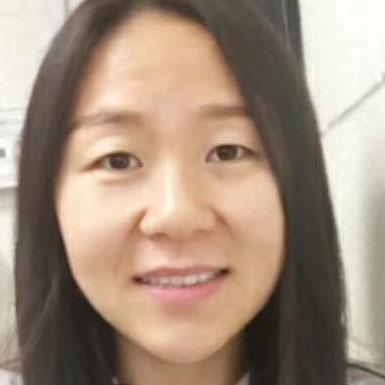

Los Alamos scientists analyzed four different co-polymer compositions of polyhydroxyalkanoates (PHAs) using molecular dynamics simulations and experimental data to determine how chemical composition and temperature impacted their strength and elasticity. These co-polymers have the potential to replace fossil fuel-based single use plastics such as grocery bags and cutlery.

The BioManufacturing with Intelligent Adaptive Control (BioManIAC) project, an ongoing LANL effort to develop bio-based plastics, recently published a paper in Macromolecules describing the glass transition temperature (Tg) of bio-based polyester. Understanding the glass transition temperature – the point at which the polymer becomes flexible instead of brittle – will help the BioManIAC team ultimately create an optimal combination of mechanical strength and elasticity in any newly developed biodegradable PHA polymers.

An atomistic-level understanding

The BioManIAC team is a collaboration among biologists, chemists, and machine learning experts The team is currently focused on a class of molecules called polyhydroxyalkanoates (PHAs). PHAs are a type of polyester made by cyanobacteria to store energy, and their chemical composition is similar to that of petroleum-based polyesters found in single use plastics like grocery bags and cutlery. In order to use PHAs instead of their fossil fuel counterparts, scientists need to know more about how to create the ideal composition of PHA polymers, or co-polymers: They want to understand the exact length of the carbon chains, or where rings or double bonds are located. These details have a critical impact on the co-polymer’s glass transition temperature.

The BioManIAC team members used a series of simulations, compared with experimental data, to pinpoint certain polymer configurations that impact the glass transition temperature of PHAs. The team used computation to examine the molecular dynamics of three distinct PHA co-polymers. The team included a modified polymer consistent force field (mPCFF), which is a computational method used to estimate interatomic interaction forces. By systematically and quantitatively analyzing various compositions and configurations of the co-polymers and blends — such as monomer mobility, number of inter-chain hydrogen bonds, and atomic correlations — the team developed a deeper atomistic-level understanding of the thermomechanical behavior of PHA-based co-polymers.

Critical bonds

Overall, the BioManIAC team concluded that the configuration of hydrogen-bonds (H-bonds) were found to play a dominant role. The data show that for a fixed composition of H-bond forming polymer “a relatively higher Tg can be expected for a configuration where the H-bonds are uniformly dispersed across the entire system as opposed to the configuration where a clustering of the H-bonds occurs due to consecutively placed H-bond forming monomer units in the backbone.”

Targeted atomistic simulations such as these for different mechanical, thermal, and transport properties, combined with in-house experiments enable the BioManIAC team to understand and rationalize systematic chemical trends in the properties, which is a crucial next step in developing bio-derived, biodegradable plastics – materials that are both environmentally friendly and functional.

Funding and Mission

This work was funded by the LANL Laboratory Directed Research and Development (LDRD) program. The research supports the Lab’s Energy Security mission and the Complex Natural and Engineered Systems capability pillar.

Reference

“Composition and Configuration Dependence of Glass-Transition Temperature in Binary Copolymers and Blends of Polyhydroxyalkanoate Biopolymers,” Macromolecules, 54, 12, 5618 (2021); DOI: https://doi.org/10.1021/acs.macromol.1c00135. Authors: Karteek K. Bejagam and Ghanshyam Pilania (MST-8), Carl N. Iverson (C-CDE), and Babetta L. Marrone (B-11).

Technical Contact: Babetta L. Marrone

Capability Enhancement

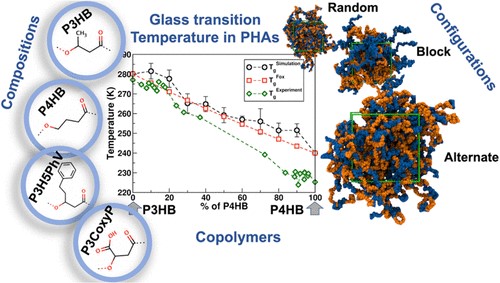

LANSCE neutron beam transport optimized via advanced collimation design techniques

LANL researchers recently developed and installed an advanced neutron beam collimation system (illustrated here) – a way of shaping a neutron beam for more precision – at the Weapons Neutron Research (WNR) Facility.

To meet the specific and stringent requirements of modern high-precision nuclear physics experimental programs, LANL researchers recently developed and installed an advanced neutron beam collimation system – a way of shaping a neutron beam for more precision – at the Weapons Neutron Research (WNR) Facility. The system, described in a paper by lead author Brad DiGiovine (P-3) and a collaborative team in Nuclear Instruments and Methods in Physics Research, delivers new capacity to conduct research into unanswered questions in physics.

Exact nuclear cross-section measurements of short-lived radioisotopes are important in both fundamental astrophysics and weapons science. Obtaining the highest quality neutron beam on a sample – for instance, a nickel-56 radioiostope campaign executed at WNR in November 2020 – required a high-resolution, holistic approach to neutron transport.

The team upgraded the facility spallation target, allowing its absolute position to be measured to +/- 68 microns with 95% confidence. The spallation target, a tungsten slug inside the target crypt that provides the source of the neutron beam, could be surveyed with laser trackers for the first time, instead of relying on optical telescopes – a critical capability to understand, in absolute terms, its precise location and orientation within the facility. That upgrade allowed the team to leverage state-of-the-art 3D modeling, Monte Carlo N-Particle modeling studies, and cutting-edge metrology instruments, to conduct facility surveys, characterize as-built geometry of critical components, perform 3D ray tracing, and execute neutron transport calculations to optimize the design of this advanced collimation system.

The spallation target included a new, retractable crown with advanced metrology infrastructure. A newly designed brass shutter insert in conjunction with an advanced collimation assembly – precisely machined and fitted brass and tungsten blocks that constrain the allowable neutron trajectories – was installed in the flight path in order to optimize neutron delivery by maximizing flux on the sample while keeping down unwanted noise of background neutrons. At the end of the flight path, unique reaction measurements can be executed at a new instrument developed in parallel to the collimation system, the “hot” Low-Energy Neutron-induced Charged-particle (z) Chamber, known as hotLENZ. In aligning the hotLENZ instrument and collimation system to the spallation target down the 30-foot flight path, the team was able to achieve precision axial alignment of better than 10 microns, approximately one-tenth the thickness of a piece of paper.

Testing the new system

The nickel-56 campaign, the first such campaign to test the new system, was conducted in November 2020. The system delivered a uniform beam tailored to a specific profile that reached the maximum possible neutron flux (a volume of neutrons moving through the cross-section at one time) and simultaneously reduced unwanted neutron background noise by several orders of magnitude.

The team continues to build on the capabilities at WNR, upgrading the spallation target again this summer. This third-generation spallation target includes on-board proton beam diagnostics, providing valuable data to streamline the tuning process, minimize the proton beam losses, and to continue the optimization of neutron production at the facility.

Mission and Funding

The work, performed under the auspices of the NNSA and Los Alamos’s Laboratory Directed Research and Development program in an Exploratory Research project, supports the Lab’s National Security mission and its Nuclear and Particle Futures capability pillar.

Researchers: Brad DiGiovine, Anastasia Georgiadou, Sean Kuvin, Hye Young Lee, Daniel Votaw (all Nuclear and Particle Physics and Applications, P-3); Lukas Zavorka (Applied and Fundamental Physics, P-2); David Ballard (Mechanical Design Engineering, AOT-MDE); Jordon Marquis (Accelerator Operations, AOT-OPS); Cecilia Lledo (Actinide Analytical Chemistry, C-AAC); and Veronika Mocko and Etienne Vermeulen (Inorganic Isotope and Actinide Chem, C-IIAC).

Reference: “A holistic approach to the optimization of neutron beam transport at the LANSCE facility,” Nuclear Instruments and Methods in Physics Research,” 1013, 165631 (2021); https://doi.org/10.1016/j.nima.2021.165631. Authors: B. DiGiovine, L. Zavorka, D.J. Ballard, C.Eiroa-Lledo, A.Georgiadoua, S.A.Kuvin, H.Y.Lee, J.S.Marquis, M.J.Mocko, V.Mocko, C.Vermeulen, D.Votawa

Technical contact: Brad DiGiovine

Chemistry

C3Lab updates enhance custom gas mixture capability

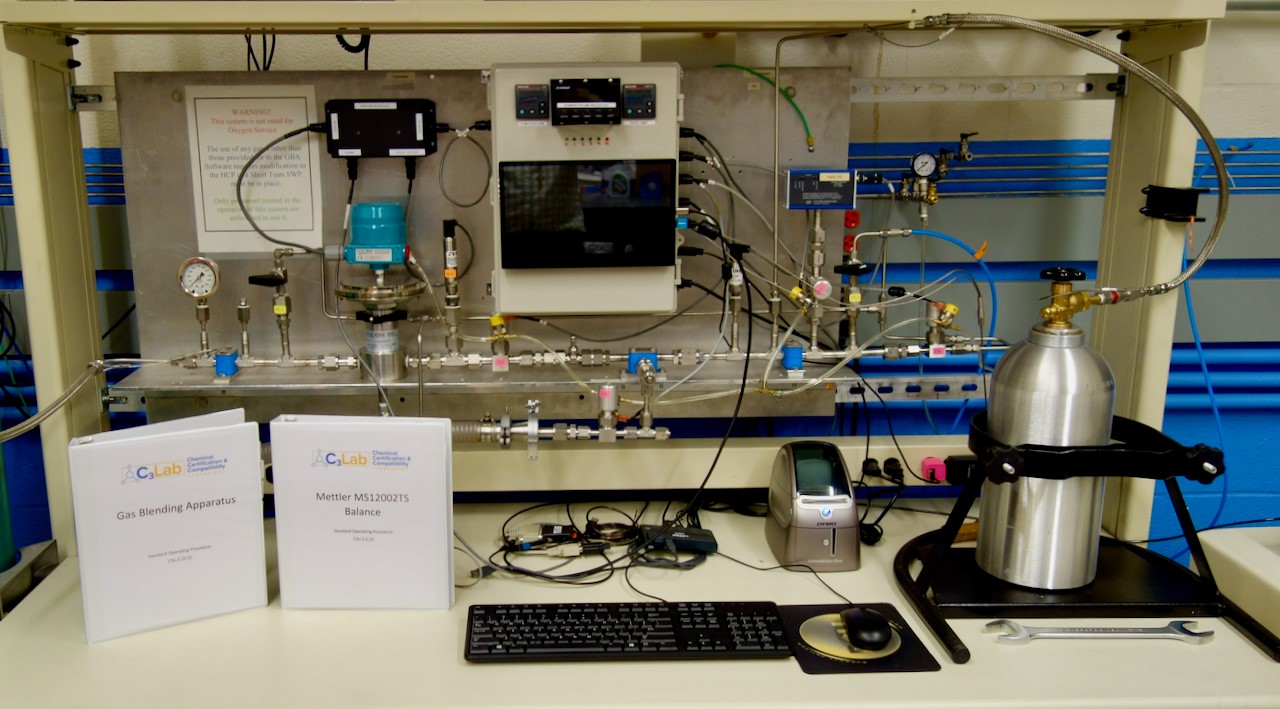

Picture of gas blending apparatus, mixing inlet (right), mixed product tank (left).

The Chemical Certification & Compatibility Lab (C3Lab) recently updated its capability to blend custom gas mixtures and provide analytical services to verify gas composition and purity to customer specification, a capability that had not been operational at LANL for approximately 10 years.

Custom gas blending is often required for unique applications at LANL, such as use with novel instruments or instrument calibration. But obtaining custom gas blends from commercial suppliers can be time consuming and expensive and often lacks satisfactory purity verification. To meet that need, the C3Lab team revamped the system to modern technology, including custom hardware and software; developed analytical procedures for both bulk composition and trace analysis; and brought the operation into a quality assurance/quality control framework compliant with NNSA Weapons Quality Policy.

The lab updated a custom manifold system with new hardware such as electronic pressure controllers, pressure transducers, gauges, and solenoid valves. These hardware updates required a custom control box to be designed and built and controlled with a Visual Basic program also developed by C3Lab. The program communicates with a certified balance and valving, which allows gas mixing to be completed with little user interfacing beyond entering the desired gas mixture composition. To conduct a filling operation, the system performs an initial leak test on the manifold, the fill tank is then baked out under vacuum to remove residual moisture, and finally the tank filling operation is completed with user inputs such as gas types, molar ratio of gases, and total tank pressure. The targeted ratios of gases are loaded and controlled using gravimetric measurements as system feedback. A binary gas mixture can be prepared in as little as two hours.

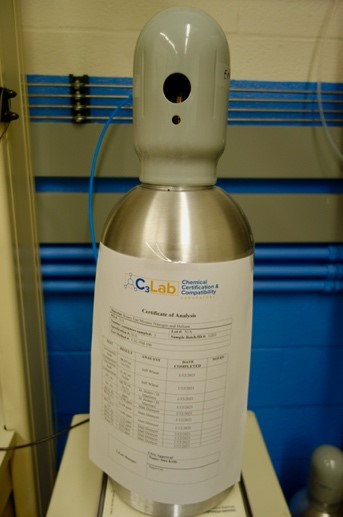

Mixed gas product complete with COA.

Analysis of the gas mixtures is accomplished by a combination of analytical techniques. Confirmation of the gravimetric bulk analysis is completed by Gas Chromatography (GC). Trace level analysis of various compounds are carried out via GC and Residual Gas Analysis (RGA). Hydrogen, oxygen, nitrogen, alkanes, and noble gas concentrations (among other analytes) can be quantitatively determined to sub-ppm detection levels. Moisture levels are determined by a dew point hygrometer to similar detection levels.

The reconstitution of this gas mixing and analysis capability can benefit many LANL programs. Recently, the C3Lab team delivered two custom, verified gas mixtures to a customer with a less than two-week turn around. Located within the Chemical Diagnostics and Engineering group (C-CDE), the C3Lab provides process materials certification and compatibility testing for Production activities. C3Lab is a general analytical laboratory fostering cooperative teamwork between LANL and NNSA sites including Lawrence Livermore National Laboratory, Savannah River site, Kansas City National Security Campus, and the Y-12 National Security Complex. C3Lab strives to be a LANL-wide resource to those in need of materials certification or compatibility testing. Inquiries into C3Lab capabilities or questions about the lab can be directed to C3Lab@lanl.gov.

Mission and Funding

This work was supported by Plutonium Sustainment and supports the Laboratory’s Nuclear Deterrence mission and the Materials capability pillar.

Technical Contact: Matt Dirmyer

Advances in catalytic hydrogenation with non-transition metals

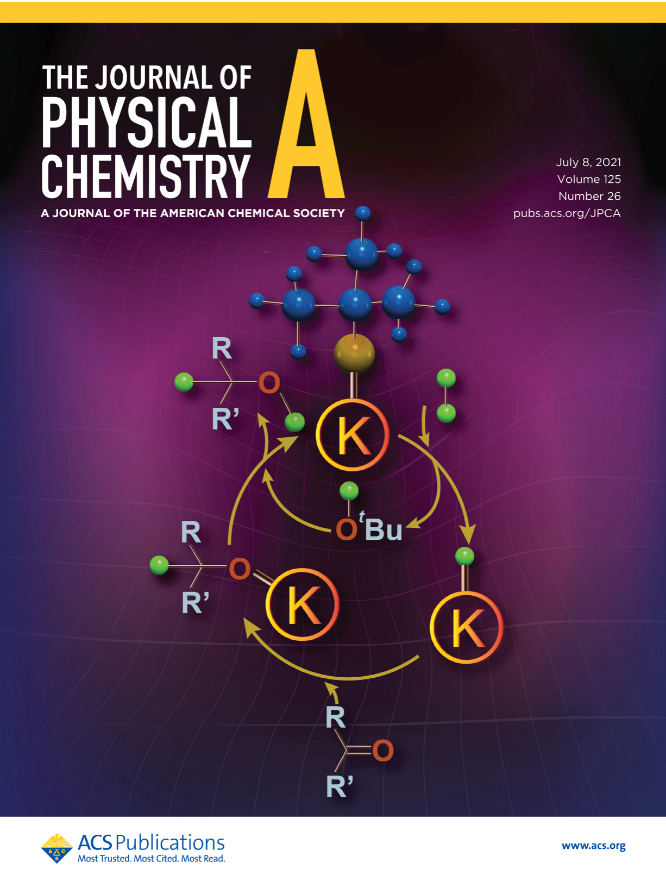

The mechanism of ketones hydrogenation with t-BuOK in tert-butanol was revised based on static and dynamic density functional theory calculations in solution-phase coupled with the reanalysis of experimental data. The reaction proceeds in three steps involving potassium hydride as an important intermediate of the catalytic process.

New research published in the Journal of Physical Chemistry A by LANL scientists Pavel Dub and Nikolay Tkachenko of the Inorganic, Isotope, and Actinide Chemistry (C-IIAC) group clarifies the mechanism of ketone hydrogenation with potassium tert-butoxide (t-BuOK). The research is featured on the journal’s inside cover.

The Department of Energy’s Basic Energy Sciences program (DOE BES) recently invested $27M for “Plastics Recycling Research and Development” and $17M for “Carbon Utilization Projects.” Efficient catalytic approaches will likely play a central role in this research.

Catalytic hydrogenations – reactions between molecular hydrogen (H2) and unsaturated organic compounds in the presence of a catalyst – are the largest-volume, human-made chemical reactions in the world, and their development has been honored with two Nobel prizes. The past few years have seen increased interest in the Earth-abundant metals as catalysts for hydrogenations. Such catalysts are urgently needed according to the latest 2017 DOE Basic Energy Sciences Workshop for Catalysis Science Report: They are present at higher abundance, are much cheaper, and are also much less toxic.

Up to now, heterogeneous catalysts based on transition noble metals such as palladium, platinum, rhodium (Rh), ruthenium (Ru), and non-noble nickel on various supports have dominated the field of chemoselective hydrogenation, while soluble Rh, Ru, and iridium molecular complexes with chiral ligands are applied predominantly for stereoselective homogeneous hydrogenations. Besides the interest in mechanistic aspects such as new modes of hydrogen activation, the following practical aspects are most often mentioned as a motivation to develop transition non-noble metal catalysts: decreased cost and increased abundance of a metal, reduced metal toxicity, and possible different reactivity of non-noble metals. Unfortunately, most of the current transition non-noble catalysts are not yet competitive for synthetic, and much less for industrial applications. In light of these limitations, catalysis with non-transition metals (e.g., sodium, potassium, calcium, magnesium, and aluminum) could be a game-changer.

The LANL researchers investigated the mechanism of t-BuOK-catalyzed ketone hydrogenation. Their work indicates a number of research directions that may help make non-transition metal catalysis practical. Overall, their results encourage renewed research into the non-transition metals for catalytic hydrogenation.

Funding and Mission

Research presented in this article was supported by the Laboratory Directed Research and Development (LDRD) program. The LANL Institutional Computing (IC) program provided access to HPC resources. The research supports the Laboratory’s Global Security mission area and the Materials for the Future Capability Pillar.

Reference

“Mechanism of Potassium tert-Butoxide-Catalyzed Ketones Hydrogenation in the Solution Phase,” Journal of Physical Chemistry A, 125, 26, 5726 (2021); https://doi.org/10.1021/acs.jpca.1c02516. Authors: Pavel A. Dub and Nikolay V. Tkachenko (C-IIAC).

Technical Contact: Pavel Dub

Physics

‘Computer vision’ techniques track plasma flow features

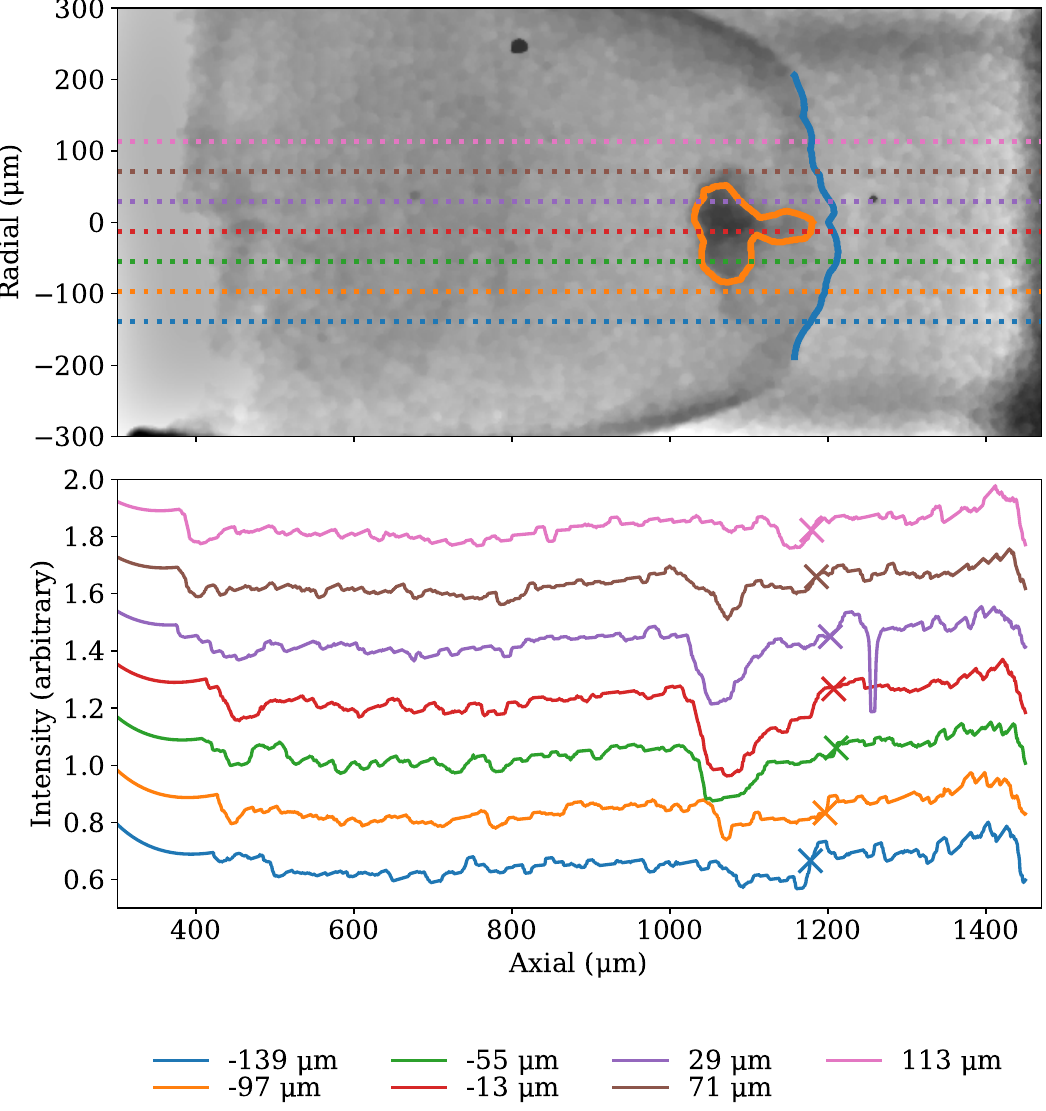

A LANL team applied “computer vision” techniques to understand and quantitatively capture features encoded within radiographs that enable the extraction of full 2D contours of plasma features.

While the hardware and techniques used in acquiring radiographs have vastly improved, the techniques used in analyzing high-energy-density (HED)plasma radiographs have remained limited. A LANL team’s recently published work in the AIP Review of Scientific Instruments describes the application of “computer vision” techniques to understand and quantitatively capture the wealth of features encoded within radiographs. The improved radiograph analysis includes denoising and contrast enhancement. The techniques also enable the extraction of full 2D contours of plasma features in a semi-automated and reproducible manner, demonstrating the advantage of 2D analysis compared to 1D lineout analysis.

Radiography is a fundamental diagnostic for understanding hydrodynamic flows in HED plasma experiments. In shock-bubble interaction (SBI) from the Marble VC (Void Collapse) campaign fielded on Omega-60 and captured in a radiograph, a shock travels from left to right and meets a bubble with different density. The sudden jump in acoustic impedance drives a number of complex effects, including shock defocusing, vorticity deposition, and compression/deformation of the bubble, which provide a test of understanding of hydrodynamics in inhomogeneous systems. Using computer vision techniques, LANL researchers extracted the shock front contour and bubble perimeter contour and overlaid them onto the radiograph. Corresponding 1D lineout positions and shock front location were also indicated. Compared to 1D lineout analysis, the computer vision techniques used the full 2D spatial information in the image to fill in important gaps, especially when a clear gradient was not present, an area where 1D analyses would fail.

These 2D contours from the experiment can be directly and quantitatively compared to synthetic radiographs produced from radiation-hydrodynamic simulations, offering a significant improvement over side-by-side visual comparisons of synthetic and experimental images. By including 2D information, rad-hydro codes can be further constrained to correctly capture radial gradients in laser or x-ray drive energy, which affect the curvature of shock fronts, as well as acoustic impedance effects, which govern the morphology of SBI. In addition, using the 2D contours of shock fronts and bubbles from orthogonal lines of sight, researchers can quantitatively assess cylindrical symmetry within HED shock tube experiments, which is important for understanding the growth of instabilities in the baroclinic vorticity of these systems.

The computer vision analysis pipeline is general enough to be applied to other campaigns, such as COAX, Radishock, and OUTI (also fielded on Omega-60), which study radiation flow in inhomogeneous systems. The researchers have not only extracted shock front contours, which emerge during the cooling of the initial Marshak wave, but have discovered secondary features, such as shock tube wall inflows and density build-ups behind the shock front which can further constrain rad-hydro simulations.

This work has also been featured in an invited talk for the High Temperature Plasma Diagnostics Conference. Participants in the project included Pawel Kozlowski, Yongho Kim, Tom Murphy, Harry Robey, Heather Johns, and Ted Perry, with Thermonuclear Plasma Physics (P-4); Tom Day, Tana Morrow, and Alex Strickland, with Engineered Materials (MST-7); Brian Haines with Eulerian Codes (XCP-2); Reid Porter with Information Sciences (CCS-3); Chris Fryer and Shane Coffing with Computational Physics and Methods (CCS-2); Todd Urbatsch and Suzannah Wood with XTD Integrated Design and Assessment (XTD-IDA); and Brian Albright with XTD Primary Physics (XTD-PRI).

Funding and Mission

The work was funded by the Office of Experimental Sciences science campaigns and supports the Lab’s Stockpile Stewardship mission and its Nuclear and Particle Futures capability pillar.

Reference

“Use of computer vision for analysis of image datasets from high temperature plasma experiments,” AIP Review of Scientific Instruments 92 (3) 033532 (2021); https://doi.org/10.1063/5.0040285. Authors: P.M. Kozlowski, Y. Kim, B.M. Haines, H.F. Robey, T.J. Murphy, H.M. Johns, and T.S. Perry.

Technical contact: Pawel Kozlowski

Self-assembly monolayer boosts efficiency and lifetime of perovskite solar cells

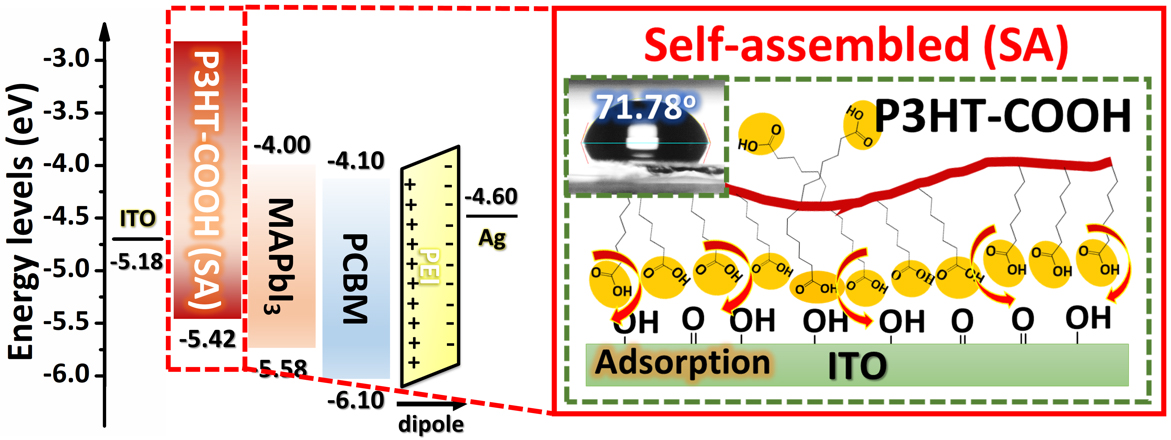

Schematic diagram of the self-assembled monolayer that serves as the interface layer for the perovskite solar cell. Researchers fabricated a monolayer of polythiophene, where the modified molecules attach themselves to conducting substrates that form a perfect atomic layer and modify the surface of the conducting oxide. This interface is a successful hole collecting electrode for the solar cell on top of it. Additionally, the perovskite layer exhibits a high degree of crystallinity that greatly enhances the power conversion efficiency and device lifetime.

A team of Center for Integrated Nanotechnologies (MPA-CINT) researchers and their collaborators has demonstrated a new fabrication technique that shows promise in fighting moisture degradation and extending solar cell device lifetimes and efficiency, even under dim-light conditions. The work was recently published in Advanced Science.

Perovskite solar cells have rapidly increased in power conversion efficiency – the amount of solar energy converted to usable electricity – from almost 4% to more than 25% in the past 10 years, becoming the champion technology for next-generation solar cell applications. Solar cell performance, however, is typically limited by eventual corrosion of the cell’s interface layer.

To meet this challenge, the CINT team developed a self-assembled monolayer in the photovoltaic cell, allowing the electroluminescent polymer polythiophene to grow a highly hydrophobic perovskite film interface layer with full coverage on the conducting oxide surface. Solar cells fabricated using this interface layer show a high efficiency of more than 20%, a long operational lifetime of over 1,000 hours, and efficient functionality under ultra-low light conditions.

The team’s work provides new insights into photovoltaic applications, including power production and use, in indoor conditions and offers helpful understanding for other device applications such as LEDs and detectors.

The Los Alamos portion of the work, performed at the CINT, was supported by the Laboratory Directed Research and Development (LDRD) program, including Mission Foundation Research funding, and a J. Robert Oppenheimer Distinguished Postdoctoral Fellowship. The work leveraged optical spectroscopy tools available at CINT and the materials characterization capabilities provided by the Advanced Photon Source. CINT is an Office of Science User Facility jointly operated by Sandia National Laboratories and LANL.

The development of a dynamic mesoscale materials science (DMMSC) capability, which would further understanding of material performance and production at the mesoscale, could benefit this research. Specifically, DMMSC would help to probe the local material structure and lattice dynamics, which play a critical role in designing an efficient interface for opto-electronic devices.

Mission and Funding

The work supports the Laboratory’s Energy Security mission area and the Materials for the Future Science Pillar.

Reference

“Facile fabrication of self-assembly functionalized polythiophene hole transporting layer for high performance perovskite solar cells,” Advanced Science, 8, 2002718 (2021); DOI: https://doi.org/10.1002/advs.202002718. Authors: Chi-Yuan Chang, Hsin-Hsiang Huang, Shu-Ling Lin, Pang-Hsiao Liu, Yang-Fang Chen, Leeyih Wang (National Taiwan University); Wei Chen (Argonne National Laboratory and University of Chicago); Hsinhan Tsai, Wanyi Nie (MPA-CINT); Fang-Chi Hsu (National United University).

Technical contact: Wanyi Nie