Microstructural Evolution and Friction at Sliding Metal Interfaces

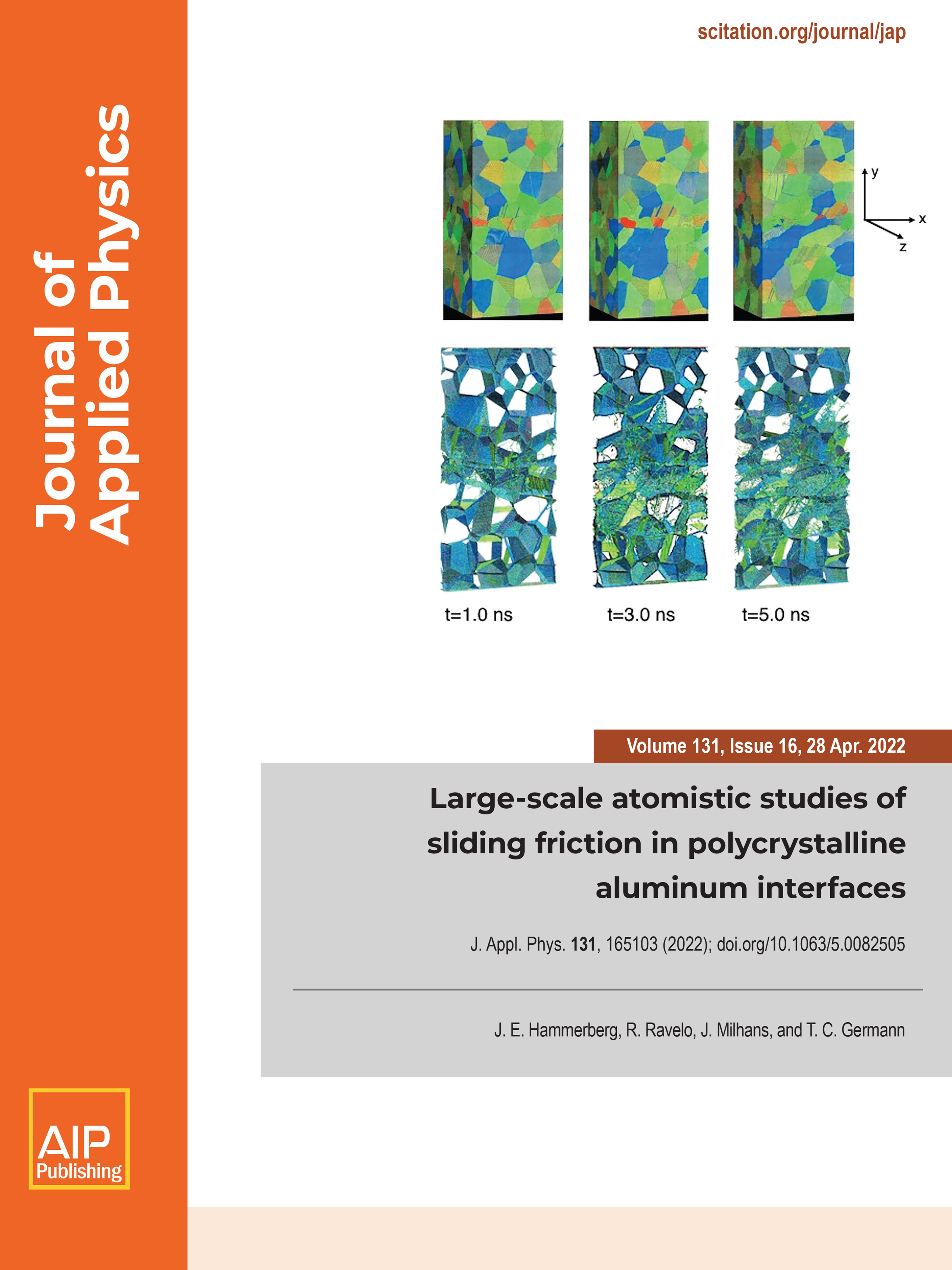

The image featured on the cover of the Journal of Applied Physics shows the early time evolution of grain structure and plastic deformation of a nanocrystalline aluminum sample with an initial 50 nm grain size, and 60 m/s sliding velocity. The top images are colored according to the local face-centered-cubic (fcc) crystal orientation. The bottom images only show defective (non-fcc) atoms.

Microstructural Evolution and Friction at Sliding Metal Interfaces

The physics of frictional interactions at ductile metal interfaces is complex, involving material mixing, grain structure transformation, and the formation of graded microstructures. At high sliding speeds, the frictional force typically exhibits velocity weakening, i.e., a decrease in the frictional force with increasing velocity with melting occurring at very high velocities. Large-scale non-equilibrium molecular dynamics (NEMD) simulations provide a window into the microscopic world of frictional dissipation. Such simulations, pioneered at LANL in the 1990s by Jim Hammerberg and Brad Holian, have provided insight into each of the phenomena mentioned above, but require extremely large length scales to model realistic polycrystalline materials, and long time scales to reach a steady state frictional heating and resistance. Only now have modern supercomputers and high-performance scalable codes made this possible.