| |

Residual Stress

Conferences |

|

paper on these measurements and FEM model

paper on these measurements and FEM model

Results:

- Shows stress maps

on two cross sections of same forging, shown in blue and red in sketch

- Periodic stress variations

from cold compression process described below

- Because of large size of

part and intricate spatial variations of stress, probably no other technique

could have measured this

- These forgings are critical

aerospace components, and residual stresses cause distortion problems

in manufacture

- Dashed lines are

zero stress contours

Highlights

of this measurement and specimen:

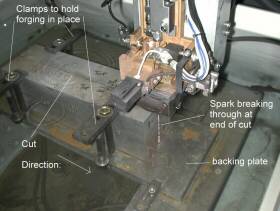

Specimen

and EDM cutting:

- 7050 Aluminum

alloy hand forging

- Original

dimensions: 107 mm X 155 mm X 710 mm (4.2" X 6.1" X

28")

- Solution

heat treated and quenched into Alcoa Proprietary Quench

- Picture

shows one piece of forging being cut by wire

EDM. This cut is the one shaded in blue

in the graphic at the top of the page. The forging had already

been cut in half lengthwise.

- Cuts were

made using 150 µm brass wire and "skim cut" settings

|

|

Quenching

Stresses :

- 7050-T74

Aluminum forging

- This is

BEFORE cold compression stress relief

- Dimensions:

107 mm X 155 mm X 710 mm (4.2" X 6.1" X 28")

- Solution

heat treated and quenched into Alcoa Proprietary Quench

- This is

from cutting forging in half lengthwise before red and blue cuts

in graphic at the top of the page.

|

|

Stress

Relief :

- A second

forging was stress relieved by overlapping cold compression

- Now the

material is 7050-T7452 Aluminum

- This is

attempt at relieving stress by uniform plastic deformation. For

plate this is done by stretching and is very effective, see measurements

of stress relief in plate.

|

|

Measure

contour :

- After EDM

cut shown in picture farther up on page, measure surface contour

- Measured

using CMM, 1 mm diameter ruby tip

- Measured

on 2 mm grid, giving about 14,000 points

- Peak-to-valley

is about 60 µm, easy to measure

- This is

for cut shaded in blue in the graphic

at the top of this page

|

|

FEM

stress calculation:

- To calculate

stress, elastically forced FEM model into opposite of measured

contour (shown just above this)

- Displacements

exaggerated to show shape

- This shows

calculation for cut shaded in blue

in the graphic at the top of this page

- The background

image on the home page is the FEM model

for the other cut, the red one in

the graphic at the top of this page

|

|

|

|